НЕВИДИМИЙ ТАНТО ІІ ексклюзивний ніж ручної роботи майстра студії Fomenko Knifes, купити замовити в Україні (Сталь - Ламінат S390™ 66-67 HRC)

- Виробник: Майстерня ножів ручної роботи FOMENKO KNIFES

- Модель: НЕВИДИМИЙ ТАНТО ІІ - ніж ручної роботи Fomenko Knifes

| Загальна довжина клинка mm: | 278±05 мм |

| Матеріал леза | Порошкова сталь S390 MICROCLEAN. Порошкова металургійна швидкорізальна сталь третього покоління, яку виготовляють із виключно чистого дрібнодисперсного порошку, виробленого на сучасному заводі BÖHLER у м. Капфенберзі, Австрії (ТО Rostyslav Dozlo) |

| Твердість клинка (метал): | Загартованість - 66-67 HRC |

| Матеріал руків'я: | Айронвуд - Ironwood (Залізне дерево), латунь хабакі |

| Довжина леза | 150±05 мм |

- Наявність: Під замовлення

Доступні варіанти

Опис

ТЕХНІЧНІ ХАРАКТЕРИСТИКИ:

Назва ножа: НЕВИДИМИЙ ТАНТО ІІ ексклюзивний ніж ручної роботи майстра студії Fomenko Knifes, купити замовити в Україні (Сталь - Ламінат S390™ 66-67 HRC)

Тип ножа: Фіксований клинок

Бренд: Студія ексклюзивних ножів ручної роботи FOMENKO KNIFES

Сталевий лист: Ціліснолитий, насткрізний монтаж на стяжку і смолу

Кут заточення леза: Загострений на 34-35 градусів

Спуски: Прямі

Зведення: 0.1-0.2 мм

Твердість леза: 66-67 HRC

Загальна довжина: 252 мм

Довжина леза: 150 мм

Ширина леза: 27 мм

Товщина леза: 4.2 мм

Довжина руків'я: 128 мм

Товщина руків'я: 24 мм

Матеріал больстера (гарда) та тильника: Латунь хабакі

Матеріал руків'я: Айронвуд - Ironwood (Залізне дерево), латунь хабакі

Колір руків'я: Коричневий

Просочення руків'я: Є

Покриття руків'я: Є

Отвір для шнурка (під темляк): Відсутнє

Темляк: Відсутній.

Піхви: Айронвуд - Ironwood (Залізне дерево), латунь хабакі

Модель: НЕВИДИМИЙ ТАНТО ІІ ексклюзивний ніж ручної роботи майстра студії Fomenko Knifes, купити замовити в Україні (Сталь - Ламінат S390™ 66-67 HRC)

Номер моделі: 058

Країна народження: Україна

Ремісник: Майстер Олександр Фоменко (Fomenko Knifes), м. Чугуїв (Chuhuyiv), Україна Студія Студія ексклюзивних ножів ручної роботи FOMENKO KNIFES

Найкраще використання: Багатофункціональний: полювання, рибальство, поділ тушки, нарізка тощо

Стан ножа: Новий

Ціна: Вказана з піхвами.

Заточений ніж – не є холодною зброєю.

Наші ножі дуже гострі, тому відкривайте та використовуйте дуже обережно. Ми не несемо відповідальності за травми, пов'язані з використанням наших ножів.

Наша продукція призначена для легального використання лише відповідальними покупцями. Ми не продаватимемо наші продукти особам молодше 18 років.

Наявність регулярно змінюється, при підтвердженні Вашого замовлення ми повідомимо про наявність або термін готовності товару. Виріб може трохи відрізнятися від представленого на фото.

Порошкова сталь S390 MICROCLEAN

Порошкова сталь S390 MICROCLEAN - це порошкова металургійна швидкорізальна сталь третього покоління, яку виготовляють із виключно чистого дрібнодисперсного порошку, виробленого на сучасному заводі з виробництва високоякісних порошкових сталей BÖHLER у м. Капфенберзі, Австрії.

Цей сплав дорогий, відноситься до преміум класу з високою твердістю та складною механічною та термічною обробкою. В результаті її твердість може досягати до 67-70 одиниць за Роквеллом, який відрізняє себе агресивним різом та високими експлуатаційними характеристиками.

Порошкова сталь S390 широко застосовується для випуску високопродуктивних інструментів (наприклад, в автомобільній галузі - зчеплення, маховик розподільного валу; у металорізанні - свердління, нарізання різьблення, зуборізні інструменти, протяжка та розгортання, кінцеві фрези, пилки; у холодній обробці металів – різні види осна інструменти для накатки різьблення, інше), тобто там, де важлива висока точність компонентів, а також сталість і тривалість його використання, тому у складі безліч елементів, що легують, дія яких спрямована на збереження властивостей сталі в будь-яких умовах.

Також сталь S390 зарекомендувала себе і в ножовому виробництві, хоч і не так давно. Зі сталі S390 у нас Ви можете купити якісні та надійні робочі та мисливські ножі середнього та невеликого розміру, які чудово покажуть себе у різанні міцних матеріалів, наприклад таких як, сухожиль і шкіри при обробці дичини. Аналогічні характеристики будуть актуальними і для професійних кухонних ножів.

Виробничий процес порошкової сталі S390 MICROCLEAN виглядає так:

Хімічний склад стали S390 MICROCLEAN наступний:

- Вуглець (С) – відповідає за міцність після проведення термічної обробки, тобто забезпечує твердість та міцність;

- Хром (Cr) – підвищує здатність сталі до загартовування, позитивно впливає на опір корозії. У даному сплаві вміст хрому невеликий, тому клинок ножа вимагає догляду для захисту від іржі. Хром також підвищує показник зносостійкості;

- Молібден (Mo) - дозволяє підвищити температуру плавлення, отже, і збереження якості клинка за підвищених температур. При цьому меч не отримує ламкість і крихкість, при підвищенні твердості - сталь стає більш пружною, підвищується опірність хімічним агресивним речовинам;

- Ванадій (V) – його наявність говорить про зростання пружності, зносостійкості, а також забезпечує інертність до хімічних впливів;

- Вольфрам (W) – за високої температури плавлення вольфраму підвищується стійкість сталі за високих температур. Є основним легуючим елементом швидкорізів;

- Кобальт (Co) - це дорога легуюча добавка позитивно позначається на жароміцності, також підвищується твердість і зносостійкість металу, при цьому ці параметри зберігаються при високих температурах і механічних навантаженнях.

Таким чином, переваги стали такі:

- висока червоностійкість, сталь добре поводиться при гартуванні, при цьому вона без проблем працює і при низьких температурах;

- дуже висока зносостійкість;

- відмінна міцність на стиск;

- висока в'язкість; ударні властивості;

- ножі зі сталі S390 мають хороші показники оброблюваності, наприклад, шліфування;

- непогані втомні властивості.

Недоліків менше, але вони таки є:

- корозійна стійкість не на найвищому рівні, тому ножу необхідний додатковий догляд, хоч і мінімальний - протирати вазеліновим маслом, яке продається в будь-якій аптеці;

- висока ціна через складність виробництва сталі.

Ніж із порошкової сталі S390 Microclean - задоволення звичайно не з дешевих, але воно того варте і стане в нагоді як для професійної діяльності, так і для активного хобі, чи то полювання, риболовля, туризм чи кулінарія.

*Варто пам'ятати, що при використанні ножа за призначенням та дбайливим поводженням, ніж прослужить Вам дуже і дуже довго.

Приємних покупок! Ми будемо раді бачити вас у лавах наших замовників!

Варто пам'ятати, що при використанні ножа за призначенням та дбайливим поводженням, ніж прослужить Вам дуже і дуже довго

Інтернет-магазин Knife.net.ua пропонує ножі ручної роботи, ексклюзивні ножі на замовлення для вибагливих чоловіків та мисливців, вироблені руками найкращих майстрів України для використання на полюванні, в нестандартних ситуаціях за вигідною ціною на замовлення або на вибір в нашому магазині. Якісний інструмент для індивідуального використання в польових умовах або на полюванні. Доставка здійснюється по всій Україні та Світові протягом кількох днів. Knife.net.ua – найкращий вибір ножів в Україні від майстрів ручної роботи..

Ну, а купити ніж з порошкової сталі ви можете на нашому сайті knife.net.ua або зв'язавшись з нами за телефоном +380961711010

Ironwood - iron wood - handmade knives

У природі залізне дерево зустрічається вкрай рідко, тому займає почесне місце в Червону книгу. Однак за своїми властивостями кожне залізне дерево не поступається щільності чавуну. Його кора витримує обстріл з вогнепальної зброї, але при цьому безнадійно тоне у воді. Варто відзначити, що це не окремий клас дерев, а ціла група, зібрана з різних порід. Вона включає в себе кілька десятків видів рослин з незвично щільною деревиною. Їх можна зустріти на кожному з континентів. Більш того, сировину використовують як в промисловій індустрії, так і в лікувальній практиці.

Що особливого в цих деревах?

Неозброєним оком розпізнати «кам’яну» породу багаторічної рослини досить складно. Особливо якщо вони знаходяться на межі зникнення. Проте їх характеризують такі особливості:

- вік таких довгожителів не менше 2-х сотень років;

- деревне волокно стійке до корозійних процесів і не псується під впливом сильних кислот;

- в корі міститься багато дубильних речовин, які захищають своїх «господарів» від всіляких паразитів, а також від грибка гнилі;

- колода обов’язково піде під воду, оскільки щільність деревини становить 1 т / м³ з урахуванням вологості 12%, з цієї причини такі породи ростуть досить повільно;

- висота кожного перевищує 25 метрів, а обхват стовбура сягає понад 200 см.

Всі ці властивості необхідні залізного дерева, щоб виживати в найсуворіших кліматичних умовах. Різкі перепади температури в Росії, африканська посуха або вологий європейський клімат не зможуть зашкодити цьому феномену природи. Такі різновиди дерев прекрасно адаптуються в будь-який несприятливій обстановці. Для цього вони оснащені чималою кількістю пристосувань, починаючи від унікальної будови стовбура / коренів і закінчуючи хімічним складом кори. У зв’язку з цим їх широко використовують у виробництві:

- меблів;

- будівельних конструкцій;

- автомобілів;

- косметичних засобів;

- елементів декору;

- підводної техніки.

Якісні та оригінальні сталеві вкладиші є чудовою прикрасою ексклюзивних та неповторних ножів Студії ексклюзивних ножів ручної роботи FOMENKO KNIFES (Україна), яка пропонує замовити та купити в інтернет-магазині https://knife.net.ua або за телефоном. . +380961711010

ЩО ТАКЕ MICARTA І G10, І НІЖ ЦІ КОМПОЗИТНІ МАТЕРІАЛИ МІЖ СЕБЕ ВІДМІНЮЮТЬСЯ

Вже десятки років композитні матеріали Micarta та G10 є безперечними лідерами у ножовій індустрії, зокрема для виробництва рукояток різної складності. Матеріали виділяються своєю доступністю, легкістю виробництва та обробки, а також високою міцністю, зносостійкістю та невибагливістю в обслуговуванні. Обидва матеріали є композитними, в їх основі лежить полімерна смола, яка доповнюється шарами полоненої тканини різного типу.

Micarta-G10-Сomposite-materials-photo-2

Матеріал Micarta - це електроізоляційний матеріал, що складається з полімерної плівки (на основі крезолоальдегідної, фенолоальдегідної, ксиленолоальдегідної смоли, або смоли із суміші фенольної сировини). Він склеєний за допомогою різних електроізоляційних паперів, тканини (в основному льону натурального або штучного походження), або інших матеріалів схожої структури, також зустрічаються варіанти зі скловолокна та вуглецевого волокна. Колір матеріалу залежить від смоли та тканинної основи, що використовується при склейці. Micarta відносно м'який матеріал і потребує ретельної ручної обробки. Тому її застосовують у виробництві рукояток для дорожчих ножів.

Мікарту зареєстровано як товарний знак американської компанії Industrial Laminates / Norplex, Inc. (Norplex-Micarta). Її вітчизняним аналогом можна розглядати матеріал під назвою "Гетінакс", який переважно використовується як основа для друкованих плат. Матеріал також має листкову пресовану структуру, яка складається з паперової основі з додаванням просочення з фенолоальдегідної або епоксидної смоли.

Мікарта на лляній основі має більш привабливий оптичний ефект під час шліфування волокон. Після завершення шліфування поверхню можна полірувати або піскоструминну обробку. У першому варіанті, поверхня матеріалу вийде гладкою, шовковистою, теплою і приємною на дотик. А в другому, матеріал стає шорстким і має матовий відтінок, крім того, надійно тримається в руці, не ковзає.

Основні характеристики Micarta:

- підвищена водостійкість;

- відмінна витримка температурних перепадів;

- міцність до механічної обробки;

- щільна структура, яка не поглинає запахи;

- мікрорельєф матеріалу не ковзає в руці навіть за умов вологої поверхні;

- щільне прилягання до леза, яке зовсім не залишає проміжків і не дає залишкам продуктів і шкідливим мікроорганізмам накопичуватися.

Матеріал G10 - це легкий, твердий і досить жорсткий композитний матеріал з текстурованою поверхнею, який переважно використовується при виготовленні рукояток як складних ножів кишенькових, так і ножів з фіксованим клинком. Даний матеріал створюється шляхом укладання декількох шарів скловолокна, ретельно просочених епоксидною смолою, у спеціальний вакуумний прес, де, під впливом стиснення та тепла, смола остаточно твердне, зберігаючи структуру склотканини.

Для матеріалу G10 характерна хороша стійкість до ударів, зносостійкість, вологостійкість, а також простота в обробці та обслуговуванні. Матеріал можна пофарбувати у різні кольори, у тому числі шарами. Поверхня G10 також може полірувати до глянсового стану, або мати шорстку протиковзну структуру, під впливом шліфувального верстата, або піскоструминної обробки.

Ключові особливості G10:

- висока стабільність базових властивостей при коливаннях температури;

- витримує високі ударні навантаження, навантаження на стиск та розтяг;

- висока загальна гідрофобність та стійкість до впливу хімікатів;

- відносно мало важить, по відношенню до загальної міцності та щільності;

- низька електропровідність;

- може набувати різних форм.

Композитні матеріали G10 та Micarta мають практично аналогічний склад та зовнішню схожість. У той же час, матеріал G10 має більш високу вогнетривкість, хоча і не є негорючим матеріалом, має більш високу міцність на стиск, вигин, удар і розрив, а також більш простий і бюджетний у виробництві. При цьому G10 поступається в плані "чіпкості" у вологих умовах, а також, тактильно, відчувається менш "натуральною".

Породи дерева для рукояті ножа

Для виготовлення рукоятей ножів використовується велика кількість різних сортів дерева, таких як карельська береза, бубінга, венге, стабілізований граб, падук, лосиний ріг, сапеле, палісандр, береста та інші. Будь-який навіть найкращий ніж, якої б міцності він не мав. Виявиться малопридатним для практичного застосування, якщо у нього погана рукоятка. Формула гарного ножа = клинок з надійної та міцної сталі + рукоятка, що зручно лежить у руці та з правильно підібраного матеріалу. Для риболовлі гарний ніж з рукояттю з берести, а для полювання краще дерев'яна рукоять, на зимовому полюванні ніж з рогу холодитиме руку без рукавички. Розглянемо докладніше найпопулярніші породи деревини.

Стабілізований граб імітує текстуру ебенового дерева. Ебен є однією з найбільш цінних порід деревини, що виростають в Африці. Висока ціна обумовлена, як рідкістю породи, тим, що деревина має велику кількість заболоні (шар дерева між корою і ядром), що дозволяє використовувати тільки порядком 30% стовбура для виробів. Крім того, ебенове дерево схильне до розтріскування, що для рукояті ножа неприйнятне. Чорний граб завдяки просочення смолами повторює текстуру ебену і не схильний до розтріскування, крім того рукояті з граба надзвичайно міцні завдяки високій щільності деревини, що робить його ідеальним матеріалом для виконання рукоятей ножів у чорному кольорі.

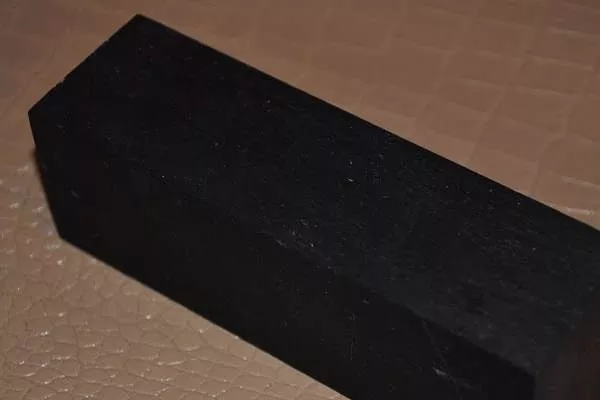

На фото (ліворуч-праворуч): залізне дерево, брусок з грабу стабілізованого смолами, рукояті зі стабілізованого граба.

Венге - це тропічний сорт деревини, що часто застосовується для виготовлення рукоятей ножів, не тільки через красиву структуру, але ще через свої фізичні властивості. Характеризується надзвичайно грубою текстурою із прямими прожилками. Має надзвичайно високу опірність на ударні навантаження, що дозволить рукояті прослужити так само довго, як і клинку ножа. Стійка до гниття. Колірна гама може сильно відрізнятися від золотисто-коричневого до темно-коричневого з чорними прожилками, для виготовлення рукоятей ножів використовуються заготовки з серцевини стовбура.

Бубінга чи інакше африканське рожеве дерево має гарну і надзвичайно насичену структуру з гарними прожилками рожевого та червоного кольору. Для рукояток підходить, як серцевина, заболонь дерева, в даному випадку, єдиною відмінністю буде колір, заболонь на кілька відтінків світліше. Надзвичайно щільний (від 800 до 960 кг/м3) і важкий сорт дерева, але рукояті з бубінгу виглядають ґрунтовно і солідно. Не схильний до розтріскування, добре пручається волозі та грибку.

Падук - надзвичайно поширене в південній півкулі дерево. Одна з найбільш водостійких порід деревини (при контакті з ґрунтом, здатна прослужити в середньому 25 років), добре підходить до ножів для риболовлі полювання в дощову та вологу погоду, тому що не ковзає в руці, навіть при попаданні вологи.

На фото (ліворуч-праворуч) рукояті з: бубінгу, венге, падука.

Одним із найдавніших матеріалів для виготовлення рукоятей ножів є кістка та роги тварин. Як і деревина матеріал природний, найчастіше для рукоятей ножів використовується лосиний ріг. Дуже складний в порівнянні з деревом матеріал для обробки, зате овчинка коштує вичинки, рукояті виходять ексклюзивними і не схожими один на одного, якщо зі стовбура дерева можна зробити величезну кількість рукоятей, то з рогу одного лося дуже обмежена кількість.

При замовленні ножа з рукояттю з лосиного рогу варто розуміти, що вона може дещо відрізнятися від тієї, що ви побачите на фотографії, тут як із відбитками пальців у людини двох абсолютно однакових не буває.

Єдиним мінусом даного матеріалу можна, мабуть, порахувати лише незручність використання на полюванні взимку, на морозі рукоятка з рогу дуже сильно охолоджується і гола рука тримати його буде дуже не комфортно.

Береста практична і зручна як матеріал для рукояті, головною її перевагою буде те, що рукоятка не ковзає в руці, навіть якщо на неї потрапила велика кількість води. Ну і безумовно, береза-це наше рідне, а не деревина з Африки та тропіків. Береста характерно містить велику кількість дьогтю, що наділяє її дезінфікуючими властивостями та захищає її від гниття, ніякі паразити та грибки на бересті не приживуться. Надзвичайно хороший матеріал, для рибальських ножів, невеликий ніж із берестяною рукояттю, може залишитися на плаву, потрапивши у воду.

Сапале - ще один з сортів деревини родом з Африки. Надзвичайно красива структура палітра від світло-рожевого до червонувато-коричневого кольору. Не схильна до розтріскування має високу твердість, від 4,1 до 4,5 одиниць за Брінеллем. Всі представлені на сайті сорти деревини, чудово підходять для виготовлення рукоятей ножа і переважно вибір ножа з конкретною рукояттю, має естетичне значення, залежно від ваших особистих уподобань.

На фото (ліворуч-праворуч) рукояті з: лосиного рогу, берести, саппеле.

Рукоятки також можуть бути виконані з декількох сортів деревини, зі вставками "сенвдич" поруч з гардою ножа, або в середині рукояті. Всі представлені на сайті сорти деревини, чудово підходять для виготовлення рукоятей ножа і переважно вибір ножа з конкретною рукояттю, має естетичне значення, залежно від ваших особистих уподобань.

Бивень моржа для руків'я ножа ручної роботи

Скільки коштує ікло моржа сьогодні?

Яка ж реальна ціна за ікл моржа, вартість якого часто незрозуміла звичайному обивателю? Як не потрапити в халепу, реагуючи на оголошення із заголовками «куплю ікло моржа» або «ікл моржа купити», як дізнатися, скільки коштує ікло моржа насправді? Щоб отримати достовірні відповіді ці питання, варто вивчити сучасний попит такий рідкісний предмет, як ікла моржа, ціна який істотно визначається як розміром, а й іншими чинниками. Враховуючи ці рекомендації, Ви можете розраховувати на найбільш вигідну пропозицію, яку можуть дати бажаючі купити ікло моржа.

- Варто знати, що ікл моржу, продати який Вам хотілося б, повинен мати максимальну цілісність, тоді його вартість виправдає Ваші найкращі очікування.

- При продажі орієнтуйтесь на актуальний курс валют, який суттєво впливає на те, скільки коштуватиме моржовий ікло, ціна його формується з урахуванням коливань курсу.

- Дуже істотна в даному питанні компетентність експертів, які оцінюють: не за кожним оголошенням «куплю ікло моржа» реально стоять професіонали, тому потрібно виявити ретельність і обережність при виборі покупця.

Вироби з іклів моржів

Ікло моржа купити мисливці за раритетами прагнуть не тільки в первозданному вигляді, не менш популярні і затребувані сувеніри та вироби, матеріалом для яких служить ікло моржа, вартість їх також може досягати пристойної суми, особливо якщо це антикварні речі. Природна привабливість бивнів, особливості їхнього кольору та структури, втілені в предметах мистецтва, створюють особливу атмосферу розкоші в будь-якому приміщенні. Це робить вироби з бивнів унікальним, статусним подарунком, актуальним у всі часи, здатним стати цінністю, що навіть передається у спадок. Найчастіше зустрічаються вироби, виготовлені жителями народів Півночі, що відбивають їхнє життя та побут:

- ножі з ручками з ікла моржа дуже дорогі і користуються популярністю серед колекціонерів і мисливці

- групові та поодинокі анімалістичні зображення (ведмеді, нерпи, олені);

- скульптури, що зображують упряж собак;

- зображення людей за характерними заняттями, наприклад мисливець;

- зображення божеств.

Морж - дуже великий звір з товстою зморшкуватою шкірою. У самців є великі шкірні нарости на шиї та плечах. Чим більші ці нарости, тим привабливішими вони здаються для самок. Товщина шкірного покриву досягає 10 см., а підшкірного жиру - 15 см. Самці набагато більші за самок - вага деяких особин досягає 2 т., але зазвичай не перевищує 800 - 1500 кг. Самки в середньому важать 500 – 800 кг. Довжина дорослих моржів - 2-3,5 м.

Молоді моржі мають темно-коричневе забарвлення шкіри із жовтуватими волосками. Дорослі тварини «лисіють» з часом, а їхня шкіра набуває світлішого відтінку. Старі особини до кінця життя стають майже рожевими.

Відмінна риса цих ластоногих – величезні бивні. Довжина їх може досягати 1 м. Вони допомагають тварині при пересуванні по слизькій поверхні та для проламування льоду. Бивни - це подовжені верхні ікла, спрямовані вниз. У самців вони більші і використовуються для битв з іншими самцями в період спарювання. Самці з найбільшими бивнями займають домінуюче місце у стаді.

Морда широка, з товстими жорсткими вусиками-щетинками на верхній губі. Очі маленькі. Вушні отвори заховані під шкірою і немає виходу назовні. Хвіст маленький. Передні ласти розвинені добре, дозволяючи моржам більш-менш нормально пересувати сушею, на відміну багатьох інших ластоногих, які здатні лише повзати землі.

Розрізняють три популяції моржів з невеликими зовнішніми відмінностями - тихоокеанську, атлантичну та популяцію моря Лаптєвих.

Тихоокеанська популяція моржів найбільша як за чисельністю, так і розмірами тварин. Вона мешкає на північному березі Східного Сибіру, на острові Врангеля, на півночі Аляски. Взимку стада моржів переміщуються на південь — у Беренгове море, до Камчатки та на південне узбережжя Аляски. За оцінками чисельність популяції становить 200 тис. тварин.

Атлантичний морж дрібніший приблизно на третину своїх тихоокеанських родичів. Мешкає на півночі Канади, Гренландії та у західному регіоні Російської Арктики. Був практично повністю винищений людиною внаслідок безконтрольного промислу. Оцінка чисельності населення - 15 - 20 тис. особин.

Лаптівська популяція моржів найнечисленніша — близько 5 тис. особин. Вона ізольована від інших популяцій у морі Лаптєвих та Карському морі.

Стан популяції та ставлення до людини

У 18-19 ст. комерційний промисел атлантичного моржа привів майже до повного зникнення цієї тварини. В даний час полювання на нього заборонено повсюдно, але деяким корінним народам півночі дозволяється добувати невелику кількість моржів, але обов'язково для власного споживання із забороною на продаж м'яса, жиру або кісток тварини. Для європейця м'ясні страви з моржу не здаються смачними, але приготовлена мова моржа вважається делікатесом.

Чукчі, Юпікські народи (Далекий Схід росії) та інуїти (Північна Америка) споживають моржеве м'ясо всю зиму, ласти консервуються і зберігаються до весни, бивні та кістки використовуються для виготовлення різних інструментів, оберегів та прикрас. Водонепроникна товста шкіра - для обробки будинків та човнів. Сучасні дешеві будівельні матеріали доступні на крайній півночі, і моржі вже не відіграють такої важливої ролі для виживання, як 100 років тому, але все одно для багатьох корінних народів залишаються затребуваними, а різьблення по шкірі моржу та її прикраса бісером є важливою формою мистецтва.

Чисельність популяцій моржів важко визначити. До кінця не зрозуміла плодючість тварин та їх смертність. Ускладнює підрахунок і складні кліматичні умови довкілля моржів. В даний час Тихоокеанський морж класифікується Законом про зникаючі види як «під загрозою». Атлантичний морж і Лаптевська населення внесено до Червоної книги і віднесено до другої (що скорочуються чисельності) і третій (рідкісні) групі рідкості відповідно.

Наслідки глобального потепління є ще одним предметом занепокоєння зоологів. Об'єм і товщина пакового льоду (товщиною не менше 3-х метрів і старше 2-х років) постійно скорочується, що позначається на народжуваності тварин і зникнення звичних місць проживання.

За різними оцінками чисельність всіх популяцій моржів становить 200-250 тис. голів.

Цікаві факти про моржі

- Під час останнього льодовикового періоду моржі було поширено до 37 градусів північної широти. Про це свідчать знайдені останки, датовані віком 28 тис. років. біля Сан-Франциско у США. На цій же широті розташований північний кордон африканського континенту, Греція, Японія, Туреччина.

- Незважаючи на свої великі розміри моржі іноді зазнають нападу косаток.

- При сильній течії моржі бивнями чіпляються за край льоду, утримуючись під водою. Також вони допомагають тваринам залазити на високий лід. Таке використання бивнів дало моржам родове ім'я Odobenus rosmarus, що з грецької перекладається як «який ходить на зубах».

- Шлунок моржа настільки великий, що народи півночі з нього робили собі водонепроникні накидки.

- У холодній воді кров'яні судини тварини сильно зменшуються, що робить шкіру тварини майже білою.

Якісні та оригінальні накладки зі сталі є чудовою прикрасою ексклюзивних та неповторних ножів майстерні Студія ексклюзивних ножів ручної роботи FOMENKO KNIFES (Україна), який пропонує замовити та купити інтернет-магазин https://knife.net.ua або замовити за тел. +380961711010

Рекомендовані товари

Доставка і оплата

Доставка і оплата

Доставка Новою Поштою

Швидкість доставки в будь-яке відділення Нової пошти в Україні фіксується оператором, але зазвичай не перевищує 1-3 календарних днів.

Готівкою

Оплата готівкою при отриманні товару.

Післяплатою на Новій Пошті (при собі необхідно мати паспорт або водійське посвідчення).

Visa и MasterCard

Оплата замовлення на карту Приват Банку.

Доставка товару можлива тільки після підтвердження платежу.

-300x300.png)

мисливський ніж/ПЕРО_2 мисливський ніж111-300x300.jpg)

/КЛОНДАЙК (шукач скарбів) н6іж ручної роботи майстра студії ножів Павла Гончаренка-300x300.png)

-300x300.png)

— середнє 2-300x300.jpg)

-600x600.png)

_заст-600x600.png)

9-300x300.jpg)

6-300x300.jpg)