ПАНСЬКИЙ ексклюзивний ніж ручної роботи майстра студії ALEKSANDR KASINEC, купити замовити в Україні (Сталь CPM® Х12МФ™ 61 HRC)

- Виробник: Майстерня ножів ручної роботи майстра ALEKSANDR KASINEC

- Модель: ПАНСЬКИЙ - ніж ручної роботи ALEKSANDR KASINEC

| Загальна довжина клинка mm: | 285±05 мм |

| Матеріал леза | Сталь марки Х12МФ - легована інструментальна штампова сталь, що виготовляється в Україні. |

| Твердість клинка (метал): | Загартованість - 61 HRC |

| Матеріал руків'я: | Больстер комбінований - нержавіюча сталь, Айронвуд - арізонське Залізне дерево (Ironwood), наскрізний монтаж на стяжку і епоксидну смолу |

| Довжина леза | 150±05 мм |

- Наявність: В наявності

Доступні варіанти

Опис

ТЕХНІЧНІ ХАРАКТЕРИСТИКИ:

Назва ножа: ПАНСЬКИЙ ексклюзивний ніж ручної роботи майстра студії ALEKSANDR KASINEC, купити замовити в Україні (Сталь CPM® Х12МФ™ 61 HRC)

Тип ножа: Фіксований клинок

Бренд: Студія Майстерня ножів ручної роботи ALEKSANDR KASINEC

Сталевий лист: Ціліснолитий, насткрізний монтаж на стяжку і смолу

Кут заточення леза: Загострений на 36 градусів

Спуски: Прямі

Зведення: 0,3 мм

Твердість леза: 61 HRC

Загальна довжина: 285 мм

Довжина леза: 150 мм

Ширина леза: 35 мм

Товщина леза: 3.8 мм

Товщина руків'я: 18 мм

Шліфування леза: Фініш - полірований в люстерко

Матеріал больстера (гарда) та тильника: Больстер комбінований - нержавіюча сталь

Матеріал руків'я: Больстер комбінований - нержавіюча сталь, Айронвуд - арізонське Залізне дерево (Ironwood), по середині зуб мамонта, наскрізний монтаж на стяжку і епоксидну смолу

Колір руків'я: Світло-Коричневий

Просочення руків'я: Відсутнє

Покриття руків'я: Полірування

Отвір для шнурка (під темляк): Відсутній

Темляк: Відсутній

Піхви: Італійська натуральна теляча шкіра чепрак рослинного вичинки та дублення 4.0 мм, оброблена апретурою для захисту від води та просякнута захисними розчинами, прошита вручну вощеною ниткою. Ручне тиснення фактурита. Вставка - шкіра пітона. Вільний підвіс та підвіс на пасок (відомого майстра ручної роботи зі шкіроюі - Андрія Курінного)

Модель: ПАНСЬКИЙ ексклюзивний ніж ручної роботи майстра студії ALEKSANDR KASINEC, купити замовити в Україні (Сталь CPM® Х12МФ™ 61 HRC)

Номер моделі: 026

Країна народження: Україна

Ремісник: Майстер Олександр Касинець (ALEKSANDR KASINEC), м. Ужгород, Україна Майстерня ножів ручної роботи ALEKSANDR KASINEC

Найкраще використання: Багатофункціональний: туризм, полювання, рибальство, кухня, поділ тушки, нарізка тощо

Стан ножа: Новий

Ціна вказана з піхвами.

Заточений ніж - не є холодною зброєю.

Наші ножі дуже гострі, тому відкривайте та використовуйте їх дуже обережно. Ми не несемо відповідальності за будь-які травми, пов’язані з використанням наших ножів.

Наша продукція призначена для легального використання лише відповідальними покупцями. Ми не будемо продавати наші продукти особам молодше 18 років.

Наявність регулярно змінюється, після підтвердження вашого замовлення ми повідомимо вас про наявність або коли товар буде готовий. Товар може дещо відрізнятися від зображеного на фото.

Х12МФ: плюси та мінуси, характеристики, відгуки.

Ножі зі сталі Х12МФ можна купити практично в будь-якому магазині, який торгує мисливськими ножами. Про те, що саме означає абревіатура «Х12МФ» з яких хімічних елементів складається сталь, чим вона хороша і чи має якісь недоліки ми розповімо в даному матеріалі.

Найпростіше з перерахованого вище - це хімічний склад, літери в назві позначають хімічні елементи, які входять до складу сталі: Х - хром, М - молібден, Ф - ванадій (не зовсім очевидно, але літера В - використовується для позначення вольфраму). Цифра 12 , що йде після Х, вказує на відсотковий вміст основного легуючого елемента – у нашому випадку хрому.

Як і у випадку з більшістю ножових сталей, замислювалася вона не для виробництва ножів, а для: профільних роликів, диропрошивних, накатних плашок, волоків і пуансонів. Чи не найширше застосування насправді. Але з низки причин, про які ми поговоримо нижче, для виробництва ножів сталь «зайшла».

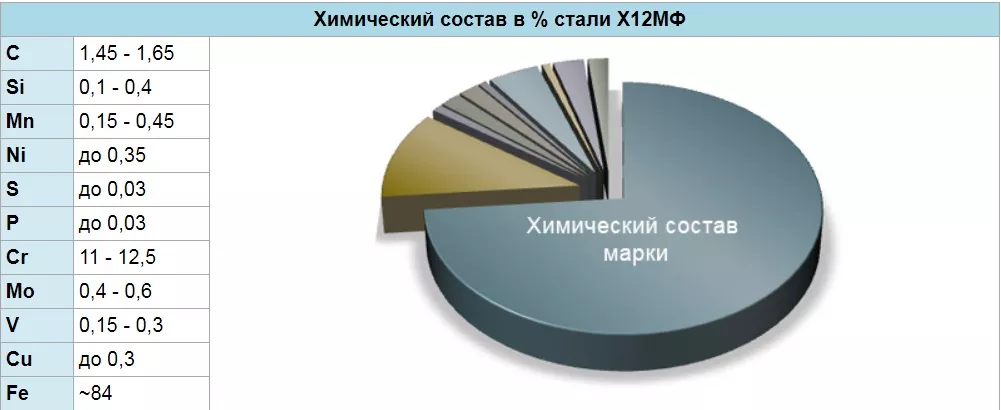

Хімічний склад стали Х12МФ

А тепер трохи наочної інфографіки про відсотковий вміст хімічних елементів у сталі. Як видно з таблиці, найбільше у складі Х12МФ (крім заліза очевидно) саме тих трьох елементів, які і становлять її назву.

У нашому випадку за легування сталі відповідає Хром, тому його висока поширеність і порівняно невисока ціна. Хром підвищує твердість та міцність, а також робить сталь корозійностійкою.

Характеристики стали Х12МФ

Якщо Ви вже відвідували різні ножові сайти, то чудово знайомі з такою характеристикою, як HRC, якщо ні, то зроблю невелике пояснення HRC – це твердість за шкалою Роквелла, чим вона вища, тим сталь міцніша, а ніж довше тримає заточення, коливатися дана характеристика може від 40 з невеликим у китайського штампування до 65-70 у японської самурайської катани.

У ножів із сталі Х12МФ HRC варіюється від 61 до 64 одиниць. Наша продукція випускається з HRC 62. Враховуючи описаний вище склад, і застосовувані хімічні елементи, Х12МФ виходить дуже зручною в обробці, має гарну загартовуваність і зносостійкість. Закордонні аналоги Х12МФ: D2, K110, Z160 , китайська Cr12MoV .

Сталь Х12МФ плюси та мінуси

Ну а тепер перейдемо, мабуть, до найважливішого для кінцевого користувача плюсів та мінусів Х12МФ.

Плюси:

- Ріжучу кромку можна заточити до гостроти бритв. Заточення вона триматиме надзвичайно довго.

- Правка ножа не завдасть проблем - алмазний брусок чи ремінь із пастою ГОІ повернуть ножу заводську гостроту.

- Міцність у 62 одиниці говорить сама за себе, ніж без проблем впорається з відкриванням консервних банок та різом по твердій деревині та кістці.

- Високі характеристики за невисокої ціни. Недорогими прийнято вважати ножі дешевше 100 $, що легко виконується за сучасного курсу американської валюти.

Зрозуміло, мінуси ми теж не обійдемо стороною вони, якщо добре пошукати знайдуться в 99% випадків.

Мінуси:

- Твердість ножа робить його виправлення в похідних умовах не найшвидшою справою, але це плата за заточку, що довго тримається.

- Сталь призначена для різання, рубати великі кістки не рекомендується. Ніж не трісне, але можливі відколи на ріжучій кромці.

- Сталь не іржавіє, але не можна сказати, що всі рідини їй дарма. Не стертий із леза лимонний сік сліди залишить. Редагування ножа усуне даний естетичний дефект, але займе це чимало часу.

Підсумки:

- Хороше співвідношення ціни та якості.

- Довго тримає заточування, але потребує часу на редагування.

- Потребує мінімального догляду, не призначений для рубання і метання.

- Здатний впоратися із завданнями від пікніка до професійного полювання.

Відгуки про ножі зі сталі Х12МФ.

Ви, напевно, бачили чимало сайтів, де купа хвалебних відгуків про матеріали та ножі. Ми не стали нічого вигадувати і просто зібрали найцікавіше, що пишуть на форумах присвяченим ножам. Можливо, частину відгуків Ви вже могли бачити на першоджерелах.

Інтернет-магазин Knife.net.ua пропонує ножі ручної роботи, ексклюзивні ножі на замовлення для вибагливих чоловіків та мисливців, вироблені руками найкращих майстрів України для використання на полюванні, в нестандартних ситуаціях за вигідною ціною на замовлення або на вибір в нашому магазині. Якісний інструмент для індивідуального використання в польових умовах або на полюванні. Доставка здійснюється по всій Україні та Світові протягом кількох днів. Knife.net.ua – найкращий вибір ножів в Україні від майстрів ручної роботи..

Ну, а купити ніж з порошкової сталі ви можете на нашому сайті knife.net.ua або зв'язавшись з нами за телефоном +380961711010

Варто пам'ятати, що при використанні ножа за призначенням та дбайливим поводженням, ніж прослужить Вам дуже і дуже довго

МАТЕРІАЛ РУКІВ'Я ЗУБ МАМОНТА

Зуб мамонта - це рідкісна сировина, що застосовується для виготовлення декоративних предметів, наприклад, рукоятей ножів, накладок на ручки пістолетів, ювелірних прикрас. Це унікальний природний елемент, добути який вдається нечасто, тому його вартість є досить високою.

Сьогодні зуб мамонта після певної обробки (стабілізації) широко застосовується майстрами кнайфмейкерами. Стабілізація – це процес полімеризації матеріалу під вакуумом з використанням жиророзчинних барвників або без них, при цьому матеріал просочується полімерними речовинами наскрізь.

МАТЕРІАЛ РУКІВ'Я ЗУБ МАМОНТА

Зуб мамонта – виробний матеріал тваринного походження. Його винятковою особливістю є той факт, що його джерелом є вимерлі звірі – мамонти. Палеонтологами було встановлено, що вони жили на Землі близько 10 тисячоліть тому, і їхня кількість була дуже велика. Зуби у мамонтів були не постійними і змінювалися приблизно чотири рази протягом життя. Зуби, що випали, які сучасні вчені знаходять під час розкопок, і стають основою для декоративних елементів, серед яких є і рукояті ножів.

Через тривале перебування в грунті матеріал набув дуже нестабільної структури – емаль отримала кам'яну твердість, а дентин, навпаки, став пухким. Але сучасні технології стабілізації матеріалів допомогли перетворити зуби мамонта на чудову основу для створення розкішних рукояток ножів. Полімерний композит забезпечує виробам стійкість до корозії та вологи, а природна основа дає унікальну текстуру та вигадливий візерунок.

Особливості матеріалу

Для створення різноманітних виробів використовують корінні зуби мамонта. Зовні вони схожі на зуби слона, проте набагато більше мають інший відтінок. З урахуванням історичної цінності та рідкості бивень мамонта цінується особливо високо, оскільки ця тварина вимерла задовго до нашої ери. Бивні доісторичних гігантів можна зустріти не тільки в палеонтологічних музеях, а й на прилавках ювелірних магазинів, їх застосовують для прикраси інтер'єру, використовують для створення різноманітних декоративних елементів - зрозуміло, не в первозданному вигляді, а в обробленому.

Вік матеріалу, за даними вчених, становить 10-40 тисяч років. Як жили мамонти, сьогодні вивчено не до кінця. Проте знайдені вченими останки цих гігантів, їхні кістки, зуби, навіть цілі туші дозволили вченим серйозно просунутися у цій галузі досліджень. Наявні дані дозволили дізнатися, який був у ссавців зовнішній вигляд, чим вони харчувалися, в яких кліматичних умовах жили, які мали особливості поведінки (наприклад, вели вони стадне або одиночне існування).

Мамонт харчувався практично тим самим, чим і сучасний слон: його раціон складала рослинна їжа. У світі тварина могла б харчуватися хвойними рослинами. Вони воліли грубий корм, який легко пережовували своїми сильними щелепами і зубами, схожими на великі пластини. Цікавою особливістю організму мамонта було те, що в міру зношування старого зуба виростав новий, який зміщував колишній і займав його місце. Таким чином, тварина могла змінити зуби кілька разів за життя. Цілком усі зуби змінювалися приблизно в десятирічний проміжок, а середня тривалість життя мамонта була 40 років. Інакше кажучи, одна тварина могла пережити в середньому чотири повні зміни корінних зубів. Саме завдяки цій особливості люди часто знаходять окремі зношені мамонтові зуби, але не зустрічають інших його слідів.

Зовнішній вигляд

Якщо розглянути зуб мамонта, то можна побачити неоднорідну поверхню з ребристими краями. Кістка, емаль та м'яка тканина в даному випадку чергуються. Матеріал має досить складну структуру:

Основою його є дентин.

Шар дентину покритий захисною емаллю.

Варто відзначити, що у мамонта було всього 4 корінні зуби та 2 бивні, які виступали назовні і служили в основному для самооборони.

Після спеціальної обробки корінний зуб можна використовуватиме виготовлення різноманітних прикрас виробів. Щільність матеріалу дуже висока і нагадує камінь. Для того, щоб обробити такий виріб, майстру потрібно витратити чимало сил і часу.

Стабілізація сировини

Щоб зуб та бивень у процесі використання та виготовлення з нього виробу не зруйнувався, застосовують технологію стабілізації. Це відповідальний етап обробки, у якому застосовуються такі технології:

Поліконденсація.

Вакуумна обробка.

Нанесення спеціальних барвників.

Всі порожнечі зуба наповнюються полімерною речовиною, за рахунок якої основа набуває надійного захисту від кліматичних впливів. Такий виріб не деформується, на ньому не з'являються тріщини, він стає здатним витримувати високу температуру. Зовнішній вигляд матеріалу також змінюється, стає більш привабливим та неповторним.

До появи цієї технології зуби і кістки мамонта для виготовлення сувенірів використовувалися рідко, тому що не мали достатньої міцності через велику кількість тріщин і розшарування всередині. Крім цього, високу твердість має зубна емаль, яка при обробці швидко призводить до непридатності пили. Стабілізований виріб набагато простіше піддавати подальшій обробці. Зуб мамонта став особливо популярним при виготовленні рукояток ножів. Він виглядає незвичайно, привабливо, а якщо додати барвник, можна створити унікальний візерунок, здатний надати навіть такій рідкісній речі особливої індивідуальності.

Ironwood - iron wood - handmade knives

У природі залізне дерево зустрічається вкрай рідко, тому займає почесне місце в Червону книгу. Однак за своїми властивостями кожне залізне дерево не поступається щільності чавуну. Його кора витримує обстріл з вогнепальної зброї, але при цьому безнадійно тоне у воді. Варто відзначити, що це не окремий клас дерев, а ціла група, зібрана з різних порід. Вона включає в себе кілька десятків видів рослин з незвично щільною деревиною. Їх можна зустріти на кожному з континентів. Більш того, сировину використовують як в промисловій індустрії, так і в лікувальній практиці.

Що особливого в цих деревах?

Неозброєним оком розпізнати «кам’яну» породу багаторічної рослини досить складно. Особливо якщо вони знаходяться на межі зникнення. Проте їх характеризують такі особливості:

- вік таких довгожителів не менше 2-х сотень років;

- деревне волокно стійке до корозійних процесів і не псується під впливом сильних кислот;

- в корі міститься багато дубильних речовин, які захищають своїх «господарів» від всіляких паразитів, а також від грибка гнилі;

- колода обов’язково піде під воду, оскільки щільність деревини становить 1 т / м³ з урахуванням вологості 12%, з цієї причини такі породи ростуть досить повільно;

- висота кожного перевищує 25 метрів, а обхват стовбура сягає понад 200 см.

Всі ці властивості необхідні залізного дерева, щоб виживати в найсуворіших кліматичних умовах. Різкі перепади температури в Росії, африканська посуха або вологий європейський клімат не зможуть зашкодити цьому феномену природи. Такі різновиди дерев прекрасно адаптуються в будь-який несприятливій обстановці. Для цього вони оснащені чималою кількістю пристосувань, починаючи від унікальної будови стовбура / коренів і закінчуючи хімічним складом кори. У зв’язку з цим їх широко використовують у виробництві:

- меблів;

- будівельних конструкцій;

- автомобілів;

- косметичних засобів;

- елементів декору;

- підводної техніки.

Якісні та оригінальні накладки зі сталі є чудовою прикрасою ексклюзивних та неповторних ножів майстерні Студія ножів ручної роботи майстра ALEKSANDR KASINEC (Україна), який пропонує замовити та купити інтернет-магазин https://knife.net.ua

Рекомендовані товари

Доставка і оплата

Доставка і оплата

Доставка Новою Поштою

Швидкість доставки в будь-яке відділення Нової пошти в Україні фіксується оператором, але зазвичай не перевищує 1-3 календарних днів.

Готівкою

Оплата готівкою при отриманні товару.

Післяплатою на Новій Пошті (при собі необхідно мати паспорт або водійське посвідчення).

Visa и MasterCard

Оплата замовлення на карту Приват Банку.

Доставка товару можлива тільки після підтвердження платежу.

-300x300.png)

мисливський ніж/ПЕРО_2 мисливський ніж111-300x300.jpg)

/КЛОНДАЙК (шукач скарбів) н6іж ручної роботи майстра студії ножів Павла Гончаренка-300x300.png)

-300x300.png)

— середнє 2-300x300.jpg)

-600x600.png)

_заст-600x600.png)

9-300x300.jpg)

6-300x300.jpg)