СКАНДІ ніж ручної роботи майстра студії Павла Гончаренка, замовити купити в Україні (Сталь - N690)

- Виробник: Майстерня ножів ручної роботи Павла Гончаренка

- Модель: СКАНДІ - студія ножів ручної роботи Павла Гончаренка, замови

| Загальна довжина клинка mm: | 255±05 мм |

| Матеріал леза | Мартенситна легована сталь N690 виробляється корпорацією Воhlег-Uddeholm Gmbh&С |

| Твердість клинка (метал): | Загартованість - 61 HRC |

| Матеріал руків'я: | Стабілізований ріг лося, бронза, гібрид з бурштину і рослини люфа в акрилі, стабілізований сувіль берези, мозаїчна темлячная трубка і пін. Темляк зі шкіряного шнура 3 мм, бусина зі сувелю берези |

| Довжина леза | 125±05 мм |

- Наявність: Під замовлення

Опис

ТЕХНІЧНІ ХАРАКТЕРИСТИКИ:

Назва ножа - СКАНДІ ніж ручної роботи майстра студії Павла Гончаренка, замовити купити в Україні (Сталь - N690)

Тип ножа: Фіксований клинок

Бренд: Студія "Ножі ручної роботи Павла Гончаренка"

Сталевий лист: Ціліснолитий, на всю довжину ножа

Спуски: Прямі

Зведення: 0.2 мм

Твердість леза: 61 HRC

Загальна довжина: 255 мм

Довжина леза: 125 мм

Ширина леза: 31 мм

Товщина лез: 4 0 мм

Товщина руків'я: 31 мм

Шліфування леза: Фініш клинка - полірований в люстерко

Матеріал больстера (гарда) та тильника: Стабілізований ріг лося

Матеріал руків'я: Стабілізований ріг лося, бронза, гібрид з бурштину і рослини люфа в акрилі, стабілізований сувіль берези, мозаїчна темлячная трубка і пін. Темляк зі шкіряного шнура 3 мм, бусина зі сувелю берези

Колір руків'я: Світло-коричневий

Просочення руків'я: Є

Покриття руків'я: Є

Отвір для шнурка (під темляк): Є

Темляк: Шкіряний шнур 3мм, бусина з айронвуду

Піхви: Сувіль берези. Італійська натуральна теляча шкіра чепрак рослинного дублення, оброблена апретурою для захисту від води та просякнута захисними розчинами, прошита вощеною ниткою. На лицевій стороні - логотип майстра. Підвіс - з'ємний

Модель: СКАНДІ ніж ручної роботи майстра студії Павла Гончаренка, замовити купити в Україні (Сталь - N690)

Номер моделі: 082

Країна народження: Україна

Ремісник: Майстер Павло Гончаренко, м. Іванків, Україна Студія ножів ручної роботи Павла Гончаренка

Найкраще використання: Полювання, туризм, рибальство, домашнє господарство, поділ тушки, нарізка

Стан ножа: Новий

Ціна вказана разом з піхвами.

Ніж заточений, не є холодною зброєю.

Наші ножі дуже гострі, тому відкривайте та використовуйте їх дуже обережно. Ми не несемо відповідальності за будь-які травми, пов’язані з використанням наших ножів.

Наша продукція призначена для легального використання лише відповідальними покупцями. Ми не будемо продавати наші продукти особам молодше 18 років.

Наявність регулярно змінюється, після підтвердження вашого замовлення ми повідомимо вас про наявність або коли товар буде готовий. Товар може дещо відрізнятися від зображеного на фото.

Особливості сталі N690

Мартенситна легована сталь N690 виробляється корпорацією Воhlег-Uddeholm Gmbh & Со, що має свої підприємства в Австрії, Німеччині, Південній та Північній Америці. Друга назва сплаву це австрійська кобальтова нержавіюча сталь. Завдяки високій якості та експлуатаційним характеристикам та плюсам її успішно реалізують у багатьох країнах світу для виготовлення ножів та інших цілей.

Сталь виготовляється за технологією електрошлакової переплавки. Має рівномірно розподілену карбідну структуру кристалічної решітки за відсутності шкідливих домішок. В результаті термічної обробки та кування ударна в'язкість матеріалу збільшується без втрати твердості. Наявність легуючих добавок у хімічному складі сталі забезпечує стійкість до корозії.

Галузь застосування

Сталь визнана хорошим матеріалом для серійного виготовлення довгомірних та тактичних ножів, технічні характеристики яких допускають експлуатацію у важких та екстремальних умовах. Леза зі сталі N690 здатні витримувати не тільки поздовжні, а й сильні бічні навантаження при дії на злам і проворотах.

Завдяки стійкості до впливу корозії та агресивних середовищ сталь застосовується при виготовленні ножів для дайвінгу, гарпунів для підводного полювання та іншого спортивного обладнання.

Цю сталь застосовують при виготовленні ножів такі відомі європейські бренди, як Вокег, Spyderco, Вепсhmade та Ехtгеmа Ratio. Виготовлені леза мають прекрасні ріжучі властивості, міцні, довговічні, добре заточуються і тримають край. Наявність легуючих елементів у складі забезпечило високу корозійну стійкість за збереження пластичності. При необхідності існує можливість термічного загартування до 60 НКР.

Техніко-фізичні характеристики сплаву дозволяють використовувати його в машинобудуванні для виготовлення інструменту, фрез, свердел, деталей підшипників та відповідальних вузлів, що працюють при високих механічних навантаженнях. Сталь відрізняється підвищеною зносостійкістю та допускає можливість термічної обробки.

Стійкість до впливу вологи та хімічних речовин дозволяє застосовувати сталь у харчовій та фармацевтичній промисловості для виготовлення ріжучого інструменту та подрібнювачів. При цьому враховується екологічна чистота матеріалу та повна відсутність домішок.

АНАЛОГИ

За своїм складом steel N690 є близьким аналогом російської сталі 95X18, німецької Х102СгМо17, японських / (3-10 і А115-10, французької 2100СО17, американської 440 С. У Швеції виробляють аналог Sandvic 12С27).

СКЛАД

Сталь N690 містить:

■ 1,08% вуглецю (С), який надає твердості матеріалу та підвищує міцність;

■ 17,3% хрому (Сг) для отримання антикорозійних властивостей, підвищення зносостійкості та зміни умов загартовування;

■ 1,1% молібдену (Мо) для зниження крихкості, підвищення пластичності та стійкості до впливу високих температур;

■ 0,1% ванадію (V) для посилення пружності металу та інертності до дії агресивних середовищ;

■ 1,5% кобальту (Со) підвищення жароміцності і поліпшення механічних властивостей;

■ 0,4% марганцю (Мп) підвищення твердості;

■ 0,4% кремнію (5|) для покращення стабільності сплаву та посилення зносостійкості.

Наявність кобальту в хімічному складі металу робить кристалічну структуру N690 більш однорідною та стійкою до механічних навантажень.

ПЛЮСИ ТА МІНУСИ СТАЛІ N690 ДЛЯ НОЖІВ

Використання австрійської сталі N690 дозволяє виготовляти якісні нержавіючі ножі різного призначення. Завдяки своїм фізико-технічним властивостям матеріал добре обробляється, здатний до термічної обробки, не схильний до корозії і продається за доступною ціною.

5*ее1 N690 це один із кращих сплавів для виготовлення красивих зносостійких клинків. Просте заточування та тривале збереження гостроти кромки роблять користування простим та зручним. Ви ніколи не пошкодуєте про купівлю або виготовлення ножа із цієї сталі.

Види поставок

Висока якість сталі Вohler N690 забезпечена застосуванням унікальної технології прокатки, розробленої виробником. Металеві листи піддаються багаторазовій гарячій обробці з прокаткою в поздовжньому та поперечному напрямку. Після цього проводиться холодне нарізування матеріалу на смуги.

Спеціально для виготовлення ножів сталь марки N690 поставляється на ринок металопрокату у вигляді сталевих смуг товщиною 3-5 мм, шириною 20-50 мм та довжиною від 250 до 1000 мм. Поперечний переріз смуг прямокутний або з підготовленим поздовжнім скосом, який позбавити виконання ковальських робіт при виготовленні леза. Сталь може мати попередню термообробку або без неї.

Все це дуже зручно, оскільки не вимагає виконання операцій з різання великих листів, дозволяє точно визначати кількість необхідного матеріалу і знижує кількість відходів.

Смуги продаються поштучно. Вартість залежить від геометричних розмірів виробу, товщини та видів попередньої заводської обробки. Для продукції металообробної промисловості здійснюються постачання листа товщиною 2-8 мм заявленого у договорі розміру. За потреби можна замовити будь-який аналог сталей типу N690. Металевий лист продається на вагу.

Що таке березовий сувель і як його заготовляють?

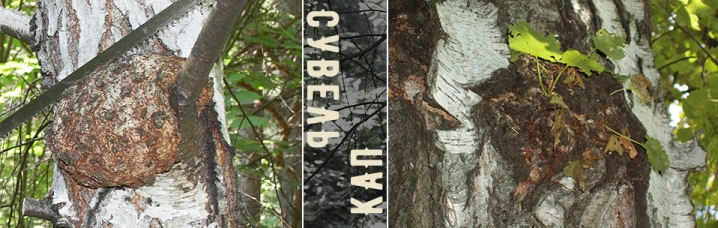

Сувель берези – незвичайна природна освіта, яку в народі часто називають березовою кісткою. Ті майстри, що профілюються на обробці дерева, знають ціну цьому незвичайному наросту. Працюючи з сувелем, можна зробити найкрасивіші вироби з приємними та якісними природними характеристиками.

Що це таке?

Сувель - це ресурсний для людини наріст, але для самої берези він не означає нічого хорошого. З'являється цей наріст через хворобу дерева (якщо говорити образно, через березовий рак). Зазвичай це грудка, скручена і сплетена, не має чіткої геометричної форми. Інша народна назва наросту – свіль. І росте цей свіль у 2, а то й у 3 рази швидше за саме дерево.

За формою він нагадує чи краплю, чи кулю, чи щось усереднене. Наріст розташовується навколо гілки або стовбура. На березі такі утворення зустрічаються часто, хоча точно сказати, чим вони викликані і чому розвиваються, не можна. Вважається, що з'являється сувель внаслідок атаки дерева грибком. Але й механічну травму берези виключати не можна.

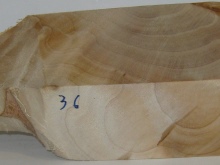

А ось деревною кісткою цей наріст називається тому, що зріз сувеля нагадує розлучення мармуру, з властивим матеріалу перерізом і променями, а тонкі частинки сувелю навіть можна переглянути наскрізь. Якась подібність із будовою кісткової тканини, дійсно, вгадується. Щоправда, щільності тканини у наросту все-таки менше – ця деревина не така міцна, як, наприклад, кап.

Трапляється, що сувель розростається до великих розмірів. Якщо приїхати до Ватикану, можна побачити там купіль, яка зроблена з цілісного шматка зрізаного з дерева сувеля. Щоправда, гігантський розмір не дорівнює якості матеріалу. Зазвичай, що менше березова кістка, то яскравіший і насиченіший внутрішній малюнок. Але в будь-якому випадку внутрішній візерунок наросту м'який, без щипчиків та голочок.

Усередині сувель нагадує перламутр – відтінком, звісно. Він буває різним, може бути білішим, темнішим, насиченим або бляклішим. Іноді сувель усередині як бурштин, буває більш коричневим, рожевим або навіть зеленуватим. Те, яким буде відтінок нутро наросту, залежить від того, де росте береза, а також від подальшого сушіння цієї частини дерева.

До речі, сувель можна спровокувати. Деякі люди просто перетягують березовий ствол або конкретну гілку дерева дротом. На місці перетяжки утворюється опуклість, що створюється річними кільцями. Але якщо дбайливе ставлення до природи у пріоритеті, робити так не варто.

Сувель ще тим вигідна природна освіта, що добре поводиться при обробці. Наріст чудово піддається шліфуванні, чудово полірується. Нарешті, головною цінністю освіти є той самий перламутровий зріз, що нагадує мармур. Він грає розлученнями на сонці, зачаровує своєю текстурою і навіть народжує якесь внутрішнє світло. Не можна точно сказати, дивлячись на наріст на березі, який він усередині, але певні прогнози можна зробити.

Чим корящий і крутіший наріст, тим його внутрішній малюнок багатший і цікавіший.

Чим відрізняється від капа?

Спочатку варто сказати, що таке кап. Він також має альтернативну народну назву – «відьмін віник». Ця освіта, на відміну сувеля, має доброякісну природу. На березовому стовбурі або гілочці виростають вузлики. Це не якась куля або велика крапля, а вузликова освіта, з безліччю шишечок, які створюють сплячі нирки (або придаткові). Ці освіти нагадують чи то шипи, чи горбки. Не дивно, якщо на капі, прямо з його нутра, зростатимуть дрібні пагони та невеликі гілочки. Зі свилем це виключено.

Відмінності між цими утвореннями є суттєвими.

Наприклад, кап - рідкісна та вдала знахідка. Вважається, що виявити його можна на одному із 3-5 тисяч дерев. Сувель знайти простіше. На березах частіше люди знаходять прикореневий кап, і він також може бути вражаючих розмірів. Обробляти кап не так просто, як сувель, все ж таки горбки, шишечки і шипи даються взнаки. Але зі шліфуванням і поліруванням проблем виникнути не повинно.

Деревина у сувеля не така міцна, як у капа. Вона міцніша щонайменше вдвічі, ніж у тієї берези, на якій кап виріс. З капа частіше роблять портсигари та скриньки, сережки, браслети, шпильки, дрібний декор. А ось різьблений візерунок на капі не створюють ніколи (ну, можливо, тільки запеклі експериментатори), адже він буде зайвим.

Фактура і текстура цього рідкісного деревного елемента не потребують надмірного декору.

Особливості заготівлі

Шукати незвичайну опуклість треба, звісно ж, у лісі. І кап, і свіль, до речі, дуже часто плутають із деревним грибом. Його назву навіть запам'ятати складно – Інонотус скошений. Але якщо говорити простіше, це те, що люди називають чайкою.

Такий гриб росте на березі, і його зустріти на дереві можна частіше, ніж сувель і тим паче кап.

Ось кілька порад щодо пошуку та заготівлі свиля.

- Спилювання свилю оптимально восени (як і капа, втім). Якщо вони дуже коряві, осіння заготівля особливо доречна.

- Спилювати наріст непросто – можливо, доведеться залучити для цього бензопилу. Щоправда, і тут може виникнути проблема – ланцюги пили швидко тупляться під дією впертого, дуже міцного наросту.

- За відсутності бензопили підійде і ручний інструмент, але тільки той, зуби якого гострі. Якщо пила буде тупувата, важко доведеться і майстру, і дереву, якого такі маніпуляції небезпечно ранять.

- Щоб на дереві не утворилося ненароком непотрібне дупло, місця зрізу сувеля потрібно швидше замазати садовим варом. Замість вару пригодиться і глина, і замазка олійною фарбою.

- Якщо знайдено звільнення величезних розмірів, варто серйозно подумати, чи спилювати освіту. Якщо відібрати у дерева такий наріст, можна завдати йому сильної шкоди: рана буде настільки серйозною, що дерево ризикує загинути.

- Початкова обробка варіативна. Можна залишити деревину на повітрі в самих натуральних умовах, але на природне сушіння піде рік, а то й два. Можна прискорити процес так: кора знімається із заготівлі, обертається газетою, поміщається у чорний пакет із поліетилену. Папір не дасть матеріалу поспішити з нагріванням, а пакет створить парниковий ефект. Якщо сувель сушиться надворі, чорний поліетилен швидко нагріється від сонця, якщо вдома – від батареї. Процес рівномірний, а отже, можна не перейматися розтріскуванням дерева. Пакет зав'язується із залишенням невеликої віддушини. На все піде приблизно 25 днів.

Але збирання, сушіння – це ще тільки початок процесу. Далі сувель треба варити.

Секрети обробки

Нижчеописаний спосіб варіння досить популярний. Більше того, він годиться, і щоб надати деревині бажаного відтінку, і щоб форсувати сушку, і щоб зробити більш виразним натуральний малюнок.

Варіння сувелі виготовляється за певною схемою.

- У каструлю укладаються лише очищені від кори заготовки. Водою вони заливаються те щоб рідина на 3 див покривала матеріал. Потім до 1 л води додають 2 столові ложки солі, ємність ставиться на вогонь. У розчин вносять тирсу: підійдуть вільхові або березові, хвоя теж пригодиться. Вони потрібні як натуральний барвник.

- Як тільки вода закипіла, вогонь зменшують і варіння триває 4 години. Якщо доводиться обробляти дуже велику заготівлю – усі 6 годин. Після чого воду зливають, деревину залишають підсихати. На другий та третій день процеси повторюються. Сумарно варіння повинне займати не менше 12 годин (до 18) протягом трьох діб поспіль.

Чому варити треба саме у сольовому розчині – спрацьовує проста фізика. У дереві є сік, і його щільність нижче за щільність сольового розчину. При варінні вода потрапляє у матеріал, починається зневоднення. Дерев'яний сік витісняється, вбирається сольовий розчин. Так відбувається елементарна дифузія рідини, і наріст висушується.

Після варіння матеріал треба обернути газетою та відправити у пакет. Наступного дня свіль все ще волога, може досихати без зайвих заходів. У крайньому випадку, підсушити матеріал можна ще один день у газеті.

Обробка наросту буває чорнової та чистової. При чорновому робиться спил у матеріалі такий, який завгодний майбутній формі виробу. Якщо це, наприклад, чаша, внутрішня частина вибирається зверху донизу. Зайва деревина видаляється рухом від стін до центру з дотриманням кута 45 градусів. Допоможе в цьому дриль чи стамеска. Витончати стінки особливо не потрібно: при висиханні вони можуть виявитися занадто крихкими, навіть розтріскування не виключені. Коли виробу надано первісну форму, його залишають на пару днів на відкритому повітрі не під прямим сонячним промінням.

Чистове оздоблення – це видалення незграбності форм, максимальне просування до кінцевого виду виробу, розкриття структури березової кістки.

Якщо в ході цієї роботи виявляються недоліки матеріалу, невеликі тріщини, виручить суміш клею та тирси. Після цього можна зачищати шорсткості: рашпілем або скребком, дротяна щітка теж працює. Діяти треба часто та дрібно, акуратно. Відшліфувати виріб можна дрилем, а краще вручну – шкіркою.

Залишиться лише очистити від пилу готовий виріб, протонувати, якщо такий задум. Дерев'яний наріст іноді обробляють лаком, іноді воском, використовується і гаряча оліфа. І цей процес довгий, трудовитрати суттєві. Але ж і коштують вироби із сувелю чимало.

Застосування

Вироби з березової кістки різноманітні – чого не створить фантазія автора. Найбільш ходовими вважаються прикраси: оригінальна біжутерія, яка сьогодні, в епоху екостилю, бохо-напрямок у дизайні особливо затребувана. Такі прикраси підійдуть тим, хто любить натуральні матеріали, природні кольори – бежевий, молочний, зелений, пісочний.

Роблять із березової кістки та дуже гарний посуд. Найпопулярнішим найменуванням сьогодні, напевно, можна вважати обробні дошки. Але й рукоятки ножів, звісно, конкурують із дошками – і це вже традиція. Матеріал щільний, простий у обробці, дуже гарний, тому рукоятки ножів будуть явно затребувані. Ножі є роками, навіть десятиліттями. Ремонт на кухні може змінитися, чимала частина посуду теж, тому ножі потрібні добротні та красиві, поза часом і мінливою модою. І рукоятки з березової кістки якнайкраще підходять.

Фігурки птахів та тварин теж дозволяє зробити сувель, адже дерев'яний візерунок так чудово візуально повторює оперення птахів, шкіру змії або шерстку тварин. Вигини матеріалу самі надихають автора, підказують майстру, що саме йому зробити. Дерев'яний малюнок може бути не самостійним виробом, а частиною оформлення картини, панно, іншого художнього об'єкта.

Словом, у того, хто любить возитися з деревом, знає ціну дерев'яному декору, виникне 100 і 1 ідея щодо березового наросту під назвою сувель. І можна бути впевненим, що прослужить виріб із березової кістки довгі роки.

ЩО ТАКЕ MICARTA І G10, І НІЖ ЦІ КОМПОЗИТНІ МАТЕРІАЛИ МІЖ СЕБЕ ВІДМІНЮЮТЬСЯ

Вже десятки років композитні матеріали Micarta та G10 є безперечними лідерами у ножовій індустрії, зокрема для виробництва рукояток різної складності. Матеріали виділяються своєю доступністю, легкістю виробництва та обробки, а також високою міцністю, зносостійкістю та невибагливістю в обслуговуванні. Обидва матеріали є композитними, в їх основі лежить полімерна смола, яка доповнюється шарами полоненої тканини різного типу.

Micarta-G10-Сomposite-materials-photo-2

Матеріал Micarta - це електроізоляційний матеріал, що складається з полімерної плівки (на основі крезолоальдегідної, фенолоальдегідної, ксиленолоальдегідної смоли, або смоли із суміші фенольної сировини). Він склеєний за допомогою різних електроізоляційних паперів, тканини (в основному льону натурального або штучного походження), або інших матеріалів схожої структури, також зустрічаються варіанти зі скловолокна та вуглецевого волокна. Колір матеріалу залежить від смоли та тканинної основи, що використовується при склейці. Micarta відносно м'який матеріал і потребує ретельної ручної обробки. Тому її застосовують у виробництві рукояток для дорожчих ножів.

Мікарту зареєстровано як товарний знак американської компанії Industrial Laminates / Norplex, Inc. (Norplex-Micarta). Її вітчизняним аналогом можна розглядати матеріал під назвою "Гетінакс", який переважно використовується як основа для друкованих плат. Матеріал також має листкову пресовану структуру, яка складається з паперової основі з додаванням просочення з фенолоальдегідної або епоксидної смоли.

Мікарта на лляній основі має більш привабливий оптичний ефект під час шліфування волокон. Після завершення шліфування поверхню можна полірувати або піскоструминну обробку. У першому варіанті, поверхня матеріалу вийде гладкою, шовковистою, теплою і приємною на дотик. А в другому, матеріал стає шорстким і має матовий відтінок, крім того, надійно тримається в руці, не ковзає.

Основні характеристики Micarta:

- підвищена водостійкість;

- відмінна витримка температурних перепадів;

- міцність до механічної обробки;

- щільна структура, яка не поглинає запахи;

- мікрорельєф матеріалу не ковзає в руці навіть за умов вологої поверхні;

- щільне прилягання до леза, яке зовсім не залишає проміжків і не дає залишкам продуктів і шкідливим мікроорганізмам накопичуватися.

Матеріал G10 - це легкий, твердий і досить жорсткий композитний матеріал з текстурованою поверхнею, який переважно використовується при виготовленні рукояток як складних ножів кишенькових, так і ножів з фіксованим клинком. Даний матеріал створюється шляхом укладання декількох шарів скловолокна, ретельно просочених епоксидною смолою, у спеціальний вакуумний прес, де, під впливом стиснення та тепла, смола остаточно твердне, зберігаючи структуру склотканини.

Для матеріалу G10 характерна хороша стійкість до ударів, зносостійкість, вологостійкість, а також простота в обробці та обслуговуванні. Матеріал можна пофарбувати у різні кольори, у тому числі шарами. Поверхня G10 також може полірувати до глянсового стану, або мати шорстку протиковзну структуру, під впливом шліфувального верстата, або піскоструминної обробки.

Ключові особливості G10:

- висока стабільність базових властивостей при коливаннях температури;

- витримує високі ударні навантаження, навантаження на стиск та розтяг;

- висока загальна гідрофобність та стійкість до впливу хімікатів;

- відносно мало важить, по відношенню до загальної міцності та щільності;

- низька електропровідність;

- може набувати різних форм.

Композитні матеріали G10 та Micarta мають практично аналогічний склад та зовнішню схожість. У той же час, матеріал G10 має більш високу вогнетривкість, хоча і не є негорючим матеріалом, має більш високу міцність на стиск, вигин, удар і розрив, а також більш простий і бюджетний у виробництві. При цьому G10 поступається в плані "чіпкості" у вологих умовах, а також, тактильно, відчувається менш "натуральною".

Рекомендовані товари

Доставка і оплата

Доставка і оплата

Доставка Новою Поштою

Швидкість доставки в будь-яке відділення Нової пошти в Україні фіксується оператором, але зазвичай не перевищує 1-3 календарних днів.

Готівкою

Оплата готівкою при отриманні товару.

Післяплатою на Новій Пошті (при собі необхідно мати паспорт або водійське посвідчення).

Visa и MasterCard

Оплата замовлення на карту Приват Банку.

Доставка товару можлива тільки після підтвердження платежу.

-300x300.png)

мисливський ніж/ПЕРО_2 мисливський ніж111-300x300.jpg)

/КЛОНДАЙК (шукач скарбів) н6іж ручної роботи майстра студії ножів Павла Гончаренка-300x300.png)

-300x300.png)

— середнє 2-300x300.jpg)

-600x600.png)

_заст-600x600.png)

9-300x300.jpg)

6-300x300.jpg)