СМІЛИВИЙ ніж ручної роботи майстра студії GARAGE ART, Сталь 9ХС 57-58 HRC

- Виробник: Студія ексклюзивних ножів ручної роботи GARAGE ART

- Модель: СМІЛИВИЙ - ніж ручної роботи GARAGE ART

| Загальна довжина клинка mm: | 280±05 мм |

| Матеріал леза | Клинок - Сталь 9ХС відноситься до категорії інструментальних сталей |

| Твердість клинка (метал): | Загартованість - 57-58 HRC |

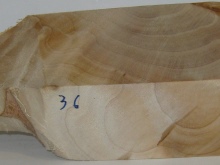

| Матеріал руків'я: | Стабілізований чорний граб, стабілізована сувіль берези. Тильник - нержавійка. Кріплення на гайку - нержавіюча сталь. Темляк, шкіряний шнур, бусина з бивня мамонта та рогу козулі |

| Довжина леза | 155±05 мм |

- Наявність: Під замовлення

Опис

ТЕХНІЧНІ ХАРАКТЕРИСТИКИ:

Brand: Студія ексклюзивних ножів ручної роботи GARAGE ART

Кут заточення леза: Загострений на 35' градусів

Спуски: Прямі

Зведення: 0.3-0.5 мм

Твердість леза: 57-58 HRC

Загальна довжина: 280 мм

Довжина леза: 155 мм

Ширина леза: 34мм

Товщина леза: 3.2 мм

Довжина руків'я: 125 мм

Товщина руків'я: 22 мм

Матеріал больстера (гарда) та тильника: G-10

Матеріал руків'я: Стабілізований чорний граб, стабілізована сувіль берези. Тильник - нержавійка. Кріплення на гайку - нержавіюча сталь. Темляк, шкіряний шнур, бусина з бивня мамонта та рогу козулі

Просочення руків'я: Так

Покриття руків'я: Так

Отвір для шнурка (під темляк): Так

Піхви: Натуральна шкіра рослинного дублення 4.0 мм, оброблена аппретурою для захисту від води та просочена захисними розчинами, жировоскове просочення, прошита вощеною ниткою. Ручне тиснення фактури. Малюнок фарбами. Фініш (Apretto) апретурою. Вільний підвіс

ТЕХНОЛОГІЯ ВИГОТОВЛЕННЯ НОЖА ВІД А до Я

Модель: СМІЛИВИЙ ніж ручної роботи майстра студії GARAGE ART (Назар Бойко), купити замовити в Україні (Сталь 9ХС)

Номер моделі: 06

Країна народження: Україна

Майстер: Майстер Назар Бойко, студія ножів "GARAGE ART", м. Львів, Україна. Студія ексклюзивних ножів ручної роботи GARAGE ART

Найкраще використання: Багатофункціональний: полювання, рибальство, туризм, домашнє господарство - нарізка, тощо.

Стан ножа: Новий

Ціна вказана з піхвами.

Заточений ніж – не є холодною зброєю.

Наші ножі дуже гострі, тому відкривайте та використовуйте дуже обережно. Ми не несемо відповідальності за травми, пов'язані з використанням наших ножів.

Наша продукція призначена для легального використання лише відповідальними покупцями. Ми не продаватимемо наші продукти особам молодше 18 років.

Наявність регулярно змінюється, при підтвердженні Вашого замовлення ми повідомимо про наявність або термін готовності товару. Виріб може трохи відрізнятися від представленого на фото.

СТАЛЬ 9ХС ДЛЯ НОЖІВ ПЛЮСИ ТА МІНУСИ

За замовчуванням сталь 9ХС відноситься до категорії інструментальних сталей. Клинок ножа з цього конструкційного матеріалу має злий різ. Край довго тримає заточування, легко правиться і заточується. Сталь швидко іржавіє в агресивному середовищі, тому ніж необхідно постійно обслуговувати.

РОЗШИФРОВКА ТА СКЛАД

Для 9ХС розшифровка стала гранично простою. Відповідно до ГОСТ 5950 у ній міститься:

-

вуглецю – 0,85 – 0,95%;

-

кремнію – 1,2 – 1,6%;

-

марганцю – 0,3 – 0,6%;

-

хрому – 0,95 – 1,25%;

-

фосфору – до 0,03%;

-

сірки – менше 0,03%;

-

нікелю – не більше 0,4%;

-

міді – менше 0,3%;

-

титану – близько 0,03%;

-

ванадія – не більше 0,15%;

-

молібдену – менше 0,2%;

-

вольфраму – до 0,2%;

-

алюмінію – близько 0,03%.

При цьому сірка та фосфор завжди є супутніми залозами добавками, в основному шкідливими. Алюміній, марганець та кремній вважаються корисними супутніми добавками при співвідношенні 0,03, 0,7 та 0,37%, відповідно. Після збільшення цих значень ці елементи автоматично стають легуючими добавками. Тому що починають серйозно впливати на властивості сталей.

В даному випадку їх відсотковий вміст алюмінію та марганцю нижче зазначених порогових значень. А відсоток кремнію вищий майже вдвічі. У будь-яких комбінаціях легатори дають понад 2,5%. І марка сталі 9ХС автоматично потрапляє до групи середньолегованих залізовуглецевих сплавів. Фактично це інструментальна сталь У9 з домішками хрому та кремнію. Відповідно, коштує дорожче, ріже краще, іржавіє так само.

Абсолютними аналогами 9ХС за твердістю ( HB 241) в групі інструментальних сталей є 9ХФ, 9ХФ, 12Х1, 9ХВГ, ХГС, ХВСГФ, 6Х3МФС, 0Х5ВФ, 8Х6НФТ, Х6ВФ, 5ХНМ, ХХ, 8Х , 4Х4ВМФС, 4Х5МФ1С, 4Х5В2ФС, 4Х2В5МФ та 5Х3В3МФС.

Тому, ніяких особливих, спеціальних властивостей і суперможливостей 9ХС не має. Просто свого часу її вибрали через досить низьку собівартість виробництва, простоту обробки, загальну доступність в асортименті середньовуглецевих інструментальних сталей.

Ні в СРСР, ні в яких країнах Європи, Америки спеціально ножові стали аж до кінця XX століття не розроблялися. Ножероби підбирали відповідні марки з існуючих.

ВЛАСТИВОСТІ ВУГЛЕЦЕВОЇ СТАЛІ

Спочатку має сталь 9ХС характеристики наступного типу:

-

твердість за Роквеллом - HRC 63 одиниці;

-

температура відпустки - 180 ° С;

-

режим загартовування - 840 - 860 ° С, охолодження в олії;

-

глибина феритного шару – 0,35 мм;

-

точкова неоднорідність – максимум 3 бали;

-

ліквація - плямиста 2 бали, подсадочна 1 бал;

-

центральна пористість – 2 бали максимум.

Структура сталі 9ХС – це зернистий перліт із залишками карбідної сітки максимум 3 бали. Зерна аустеніту мають величину 8 балів максимум. При відкритій виплавці сталь 9ХС містить силікати, нітрити та оксиди менше 3 балів та сульфіти менше 2,5 балів. При електрошлаковому переплаві ці показники в 1,5 – 2,5 рази нижчі.

Для рядового користувача гострого інструменту набагато важливіше експлуатаційні властивості клинка з 9ХС:

-

складно кувати, особливо ручним способом;

-

легко точити, буквально за 5 – 6 рухів по каменю, ріжуча кромка повністю відновлює гостроту;

-

для виправлення леза можна використовувати недорогі сталеві мусати та точильні пристрої;

-

рез агресивний, злий, ніякого «замилювання» та ковзання по продукту;

-

кислоти, луги, соляні розчини з риби, м'яса, фруктів та інших продуктів викликають корозію сталі;

-

клинок повинен обслуговуватися відразу після закінчення роботи - промиватися струменем води, витиратися ганчіркою насухо;

-

при будь-якій тривалій перерві використання клинка з 9ХС лезо змащується олією.

Пояснити словами, як сталь 9ХС для ножів ріже, стругає, розсікає та коле, дуже складно словами. Необхідно пробувати ці дії на потрібних матеріалах. Тільки після цього, багато користувачів більше ніколи не купують ножі з нержавіючої сталі. Хоча вони й не потребують догляду, окрім як заточування.

ГАЛУЗЬ ЗАСТОСУВАННЯ

Офіційне пояснення, марка 9ХС яка сталь, наводиться у ГОСТ 5950, остання редакція 2000 року. У таблиці А зазначено, що цей конструкційний матеріал розроблений спеціально для наступних інструментів:

-

тавра для холодного способу нанесення;

-

штемпелі холодного машинного методу;

-

фрези з металу;

-

гребінки загального призначення;

-

плашки та мітчики різьбонарізні;

-

розгортки, зенкери, свердла всіх типів.

Для порівняння, дешевша 13Х із цієї ж серії інструментальних сталей, офіційно створена для гравірувальних фрез, шаберів, хірургічних скальпелів, лез для гоління і ножів небезпечних бритв. За замовчуванням сталь 9ХС має плюси мінуси наступного виду:

-

складне кування;

-

необхідність постійного обслуговування;

-

низька корозійна стійкість;

-

дорожнеча в порівнянні з вуглецевими нелегованими сталями;

-

швидке заточування;

-

низька ціна порівняно з нержавіючими, порошковими та дамаськими сталями;

-

легке виправлення;

-

висока ріжуча здатність;

-

довге утримання заточування.

У результаті, холодно-штампова сталь 9ХС, що розглядається, придатна для виготовлення клинків ножів будь-яких категорій користування. Лезо може мати спуски прямим клином від обуха, середини, опуклою та увігнутою лінзою, одностороннє заточення клином та ложкою, як у Якутського ножа.

Основним плюсом є дрібна структура фериту та карбідів. На відміну від нержавіючої сталі кромка виходить рівна і гладка, без мікроскопічних зубчиків серрейтора.

ТОП 15 НОЖІВ ІЗ СТАЛІ 9ХС

За ступенем популярності ніж із вуглецевої сталі цього типу представлений у рейтингу наступним чином:

-

Якутський.

Складна форма спусків та просторової геометрії клинка. Необхідний навичка заточування та виправлення. Ніж вважається національним. Придатний для полювання, туризму, риболовлі, збирання грибів, повсякденного носіння та особистого захисту.

-

Мисливський

Заточування вистачає на обробку туші лося, без правки у процесі робіт. У ножах для добору тварин меч повинен бути заточений від середини. Оскільки сталь крихка для потужних ударних навантажень. При попаданні в ребро метал швидше за все зламається.

-

Рибальський

Вуглецева сталь ідеально підходить для філейних ножів. Є обмеження за товщиною клинка. Зате, точити його можна на камені, що випадково підвернувся. Рибальські ножі зазвичай мають рукоятку з еластомеру для забезпечення позитивної плавучості.

-

Пчак

Ще один національний ніж. Але цього разу для кухні. Тяжкий масивний клинок зміщує баланс вперед. Довго користуватись інструментом незручно. Тому частіше використовується кухарями чоловіками, а не слабкою статтю.

-

Кукрі

Спочатку створювався для рубання кущів, інших сільськогосподарських робіт. Потім став легендарною зброєю англійських найманців у колоніях – гуркхів. Має високі декоративні властивості. використовується як подарунок, колекційний, сувенірний нож. Рідше використовують на полюванні для добору звіра.

-

Туристичний

Багатозадачний інструмент із середніми характеристиками у кожній окремо взятій області. Відмінно коле, ріже, рубає, найчастіше ще й пиляє. Клинок масивний, можна копати ґрунт, затискати лезо в камінні, щоб ходити або висіти на рукояті. Урізана версія диверсійного ножа із обмеженим побутовим функціоналом.

-

Універсал

Аналог Туриста, проте, скромніший у розмірах. Найчастіше, з клиноподібними спусками від середин, п'ятою, пальцевими упорами та/або радіусами. Товщина в обусі 2-3 мм, можливі винятки в обидві сторони. Ножі з іржавіючої сталі зазвичай упаковуються в шкіряні піхви.

-

Шийний

Компактний ніж із обмеженим функціоналом. Лезо найчастіше товсте, заточування від обуха. Класичні та оригінальні форми клинка, конструкцій та матеріалів рукояток. Можливе носіння мечем вниз і вгору, зі спеціальними фіксуючими пристроями піхов.

-

Фінський

Ножова класика часів СРСР, становлення республіки та післявоєнного періоду. Величезна різноманітність форм, типорозмірів, навершів та потиличників рукояток. Клинок профілю "щучка", спуски від середини, часто з ребром жорсткості - долом. Рукоятка дерев'яна, овальна в поперечнику, з навершям у формі грибка, дзьоба або сучка, вирізаним із тіла деревини.

-

Фінка НКВС

Лідер продажу з моменту надходження ножів цього у вільний оборот у РФ. Розвинена гарда з довгими вигнутими вусами, багатозадачне лезо фінського типу. Зброя часів Великої Вітчизняної війни, переобладнана під цивільні завдання.

-

Філейний

Спеціальний варіант ножа рибальського та кухонного. Тонкий довге вузьке лезо зі спусками від обуха. Рукоять з не ковзного матеріалу, що не вбирає запахи, барвники та слиз, кров. Найчастіше, з п'ятою та переднім пальцевим упором.

-

Складаний

Для повсякденного носіння чи спеціальних завдань. Не обмежень по конструкції, формі леза, рукояті, механізмам відкривання та фіксації. Клинок зазвичай полірований або, навпаки, з характерними слідами кування на голомені.

-

Ціліснометалічний

Зручний інструмент для кухні, полювання, риболовлі, збирання грибів, туризму та щоденного носіння з ідеальним балансуванням. Компактна рукоятка із двох симетричних плашок, приклепаних до хвостовика. Будь-які типи заточування, форми, розміри, сфери застосування.

-

Сербська

Модна кухонна сокира особливої форми. Найчастіше викований ручним способом. Клинок зі слідами кування, іноді декоративним травленням під Дамаск.

-

Великий шеф

Два варіанти виконання - європейський кухонник з довгим широким клинком профілю Drop Point , або японська сокира санток особливої форми.

У споконвічній суперечці, яка сталь краща для мисливського ножа, переможця не може бути за визначенням. Оскільки, вже починаючи з області розв'язуваних завдань та вимог користувача до клинка, починаються розбіжності, часом прямо протилежні один одному.

Чорний граб

Чорний граб штучного моріння - один із найпопулярніших матеріалів під рукояті для ножів.

Морений граб чорного кольору імітує текстуру ебенового дерева, що є рідкісною і цінною породою деревини.

До особливостей чорного граба можна віднести:

- Висока твердість матеріалу;

- В'язкість;

- Стійкість до ударних навантажень.

Допуски у розмірах +/- 1-2мм.

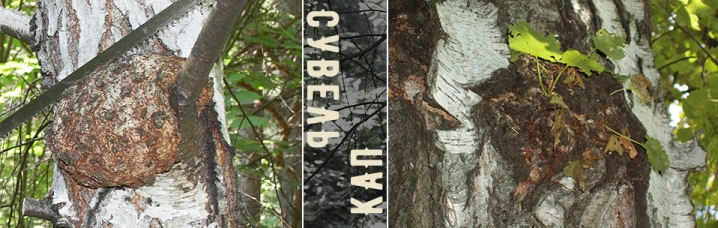

Що таке березовий сувель і як його заготовляють?

Сувель берези – незвичайна природна освіта, яку в народі часто називають березовою кісткою. Ті майстри, що профілюються на обробці дерева, знають ціну цьому незвичайному наросту. Працюючи з сувелем, можна зробити найкрасивіші вироби з приємними та якісними природними характеристиками.

Що це таке?

Сувель - це ресурсний для людини наріст, але для самої берези він не означає нічого хорошого. З'являється цей наріст через хворобу дерева (якщо говорити образно, через березовий рак). Зазвичай це грудка, скручена і сплетена, не має чіткої геометричної форми. Інша народна назва наросту – свіль. І росте цей свіль у 2, а то й у 3 рази швидше за саме дерево.

За формою він нагадує чи краплю, чи кулю, чи щось усереднене. Наріст розташовується навколо гілки або стовбура. На березі такі утворення зустрічаються часто, хоча точно сказати, чим вони викликані і чому розвиваються, не можна. Вважається, що з'являється сувель внаслідок атаки дерева грибком. Але й механічну травму берези виключати не можна.

А ось деревною кісткою цей наріст називається тому, що зріз сувеля нагадує розлучення мармуру, з властивим матеріалу перерізом і променями, а тонкі частинки сувелю навіть можна переглянути наскрізь. Якась подібність із будовою кісткової тканини, дійсно, вгадується. Щоправда, щільності тканини у наросту все-таки менше – ця деревина не така міцна, як, наприклад, кап.

Трапляється, що сувель розростається до великих розмірів. Якщо приїхати до Ватикану, можна побачити там купіль, яка зроблена з цілісного шматка зрізаного з дерева сувеля. Щоправда, гігантський розмір не дорівнює якості матеріалу. Зазвичай, що менше березова кістка, то яскравіший і насиченіший внутрішній малюнок. Але в будь-якому випадку внутрішній візерунок наросту м'який, без щипчиків та голочок.

Усередині сувель нагадує перламутр – відтінком, звісно. Він буває різним, може бути білішим, темнішим, насиченим або бляклішим. Іноді сувель усередині як бурштин, буває більш коричневим, рожевим або навіть зеленуватим. Те, яким буде відтінок нутро наросту, залежить від того, де росте береза, а також від подальшого сушіння цієї частини дерева.

До речі, сувель можна спровокувати. Деякі люди просто перетягують березовий ствол або конкретну гілку дерева дротом. На місці перетяжки утворюється опуклість, що створюється річними кільцями. Але якщо дбайливе ставлення до природи у пріоритеті, робити так не варто.

Сувель ще тим вигідна природна освіта, що добре поводиться при обробці. Наріст чудово піддається шліфуванні, чудово полірується. Нарешті, головною цінністю освіти є той самий перламутровий зріз, що нагадує мармур. Він грає розлученнями на сонці, зачаровує своєю текстурою і навіть народжує якесь внутрішнє світло. Не можна точно сказати, дивлячись на наріст на березі, який він усередині, але певні прогнози можна зробити.

Чим корящий і крутіший наріст, тим його внутрішній малюнок багатший і цікавіший.

Чим відрізняється від капа?

Спочатку варто сказати, що таке кап. Він також має альтернативну народну назву – «відьмін віник». Ця освіта, на відміну сувеля, має доброякісну природу. На березовому стовбурі або гілочці виростають вузлики. Це не якась куля або велика крапля, а вузликова освіта, з безліччю шишечок, які створюють сплячі нирки (або придаткові). Ці освіти нагадують чи то шипи, чи горбки. Не дивно, якщо на капі, прямо з його нутра, зростатимуть дрібні пагони та невеликі гілочки. Зі свилем це виключено.

Відмінності між цими утвореннями є суттєвими.

Наприклад, кап - рідкісна та вдала знахідка. Вважається, що виявити його можна на одному із 3-5 тисяч дерев. Сувель знайти простіше. На березах частіше люди знаходять прикореневий кап, і він також може бути вражаючих розмірів. Обробляти кап не так просто, як сувель, все ж таки горбки, шишечки і шипи даються взнаки. Але зі шліфуванням і поліруванням проблем виникнути не повинно.

Деревина у сувеля не така міцна, як у капа. Вона міцніша щонайменше вдвічі, ніж у тієї берези, на якій кап виріс. З капа частіше роблять портсигари та скриньки, сережки, браслети, шпильки, дрібний декор. А ось різьблений візерунок на капі не створюють ніколи (ну, можливо, тільки запеклі експериментатори), адже він буде зайвим.

Фактура і текстура цього рідкісного деревного елемента не потребують надмірного декору.

Особливості заготівлі

Шукати незвичайну опуклість треба, звісно ж, у лісі. І кап, і свіль, до речі, дуже часто плутають із деревним грибом. Його назву навіть запам'ятати складно – Інонотус скошений. Але якщо говорити простіше, це те, що люди називають чайкою.

Такий гриб росте на березі, і його зустріти на дереві можна частіше, ніж сувель і тим паче кап.

Ось кілька порад щодо пошуку та заготівлі свиля.

- Спилювання свилю оптимально восени (як і капа, втім). Якщо вони дуже коряві, осіння заготівля особливо доречна.

- Спилювати наріст непросто – можливо, доведеться залучити для цього бензопилу. Щоправда, і тут може виникнути проблема – ланцюги пили швидко тупляться під дією впертого, дуже міцного наросту.

- За відсутності бензопили підійде і ручний інструмент, але тільки той, зуби якого гострі. Якщо пила буде тупувата, важко доведеться і майстру, і дереву, якого такі маніпуляції небезпечно ранять.

- Щоб на дереві не утворилося ненароком непотрібне дупло, місця зрізу сувеля потрібно швидше замазати садовим варом. Замість вару пригодиться і глина, і замазка олійною фарбою.

- Якщо знайдено звільнення величезних розмірів, варто серйозно подумати, чи спилювати освіту. Якщо відібрати у дерева такий наріст, можна завдати йому сильної шкоди: рана буде настільки серйозною, що дерево ризикує загинути.

- Початкова обробка варіативна. Можна залишити деревину на повітрі в самих натуральних умовах, але на природне сушіння піде рік, а то й два. Можна прискорити процес так: кора знімається із заготівлі, обертається газетою, поміщається у чорний пакет із поліетилену. Папір не дасть матеріалу поспішити з нагріванням, а пакет створить парниковий ефект. Якщо сувель сушиться надворі, чорний поліетилен швидко нагріється від сонця, якщо вдома – від батареї. Процес рівномірний, а отже, можна не перейматися розтріскуванням дерева. Пакет зав'язується із залишенням невеликої віддушини. На все піде приблизно 25 днів.

Але збирання, сушіння – це ще тільки початок процесу. Далі сувель треба варити.

Секрети обробки

Нижчеописаний спосіб варіння досить популярний. Більше того, він годиться, і щоб надати деревині бажаного відтінку, і щоб форсувати сушку, і щоб зробити більш виразним натуральний малюнок.

Варіння сувелі виготовляється за певною схемою.

- У каструлю укладаються лише очищені від кори заготовки. Водою вони заливаються те щоб рідина на 3 див покривала матеріал. Потім до 1 л води додають 2 столові ложки солі, ємність ставиться на вогонь. У розчин вносять тирсу: підійдуть вільхові або березові, хвоя теж пригодиться. Вони потрібні як натуральний барвник.

- Як тільки вода закипіла, вогонь зменшують і варіння триває 4 години. Якщо доводиться обробляти дуже велику заготівлю – усі 6 годин. Після чого воду зливають, деревину залишають підсихати. На другий та третій день процеси повторюються. Сумарно варіння повинне займати не менше 12 годин (до 18) протягом трьох діб поспіль.

Чому варити треба саме у сольовому розчині – спрацьовує проста фізика. У дереві є сік, і його щільність нижче за щільність сольового розчину. При варінні вода потрапляє у матеріал, починається зневоднення. Дерев'яний сік витісняється, вбирається сольовий розчин. Так відбувається елементарна дифузія рідини, і наріст висушується.

Після варіння матеріал треба обернути газетою та відправити у пакет. Наступного дня свіль все ще волога, може досихати без зайвих заходів. У крайньому випадку, підсушити матеріал можна ще один день у газеті.

Обробка наросту буває чорнової та чистової. При чорновому робиться спил у матеріалі такий, який завгодний майбутній формі виробу. Якщо це, наприклад, чаша, внутрішня частина вибирається зверху донизу. Зайва деревина видаляється рухом від стін до центру з дотриманням кута 45 градусів. Допоможе в цьому дриль чи стамеска. Витончати стінки особливо не потрібно: при висиханні вони можуть виявитися занадто крихкими, навіть розтріскування не виключені. Коли виробу надано первісну форму, його залишають на пару днів на відкритому повітрі не під прямим сонячним промінням.

Чистове оздоблення – це видалення незграбності форм, максимальне просування до кінцевого виду виробу, розкриття структури березової кістки.

Якщо в ході цієї роботи виявляються недоліки матеріалу, невеликі тріщини, виручить суміш клею та тирси. Після цього можна зачищати шорсткості: рашпілем або скребком, дротяна щітка теж працює. Діяти треба часто та дрібно, акуратно. Відшліфувати виріб можна дрилем, а краще вручну – шкіркою.

Залишиться лише очистити від пилу готовий виріб, протонувати, якщо такий задум. Дерев'яний наріст іноді обробляють лаком, іноді воском, використовується і гаряча оліфа. І цей процес довгий, трудовитрати суттєві. Але ж і коштують вироби із сувелю чимало.

Застосування

Вироби з березової кістки різноманітні – чого не створить фантазія автора. Найбільш ходовими вважаються прикраси: оригінальна біжутерія, яка сьогодні, в епоху екостилю, бохо-напрямок у дизайні особливо затребувана. Такі прикраси підійдуть тим, хто любить натуральні матеріали, природні кольори – бежевий, молочний, зелений, пісочний.

Роблять із березової кістки та дуже гарний посуд. Найпопулярнішим найменуванням сьогодні, напевно, можна вважати обробні дошки. Але й рукоятки ножів, звісно, конкурують із дошками – і це вже традиція. Матеріал щільний, простий у обробці, дуже гарний, тому рукоятки ножів будуть явно затребувані. Ножі є роками, навіть десятиліттями. Ремонт на кухні може змінитися, чимала частина посуду теж, тому ножі потрібні добротні та красиві, поза часом і мінливою модою. І рукоятки з березової кістки якнайкраще підходять.

Фігурки птахів та тварин теж дозволяє зробити сувель, адже дерев'яний візерунок так чудово візуально повторює оперення птахів, шкіру змії або шерстку тварин. Вигини матеріалу самі надихають автора, підказують майстру, що саме йому зробити. Дерев'яний малюнок може бути не самостійним виробом, а частиною оформлення картини, панно, іншого художнього об'єкта.

Словом, у того, хто любить возитися з деревом, знає ціну дерев'яному декору, виникне 100 і 1 ідея щодо березового наросту під назвою сувель. І можна бути впевненим, що прослужить виріб із березової кістки довгі роки.

МАТЕРІАЛ РУКІВ'Я ЗУБ МАМОНТА

Зуб мамонта - це рідкісна сировина, що застосовується для виготовлення декоративних предметів, наприклад, рукоятей ножів, накладок на ручки пістолетів, ювелірних прикрас. Це унікальний природний елемент, добути який вдається нечасто, тому його вартість є досить високою.

Сьогодні зуб мамонта після певної обробки (стабілізації) широко застосовується майстрами кнайфмейкерами. Стабілізація – це процес полімеризації матеріалу під вакуумом з використанням жиророзчинних барвників або без них, при цьому матеріал просочується полімерними речовинами наскрізь.

Зуб мамонта – виробний матеріал тваринного походження. Його винятковою особливістю є той факт, що його джерелом є вимерлі звірі – мамонти. Палеонтологами було встановлено, що вони жили на Землі близько 10 тисячоліть тому, і їхня кількість була дуже велика. Зуби у мамонтів були не постійними і змінювалися приблизно чотири рази протягом життя. Зуби, що випали, які сучасні вчені знаходять під час розкопок, і стають основою для декоративних елементів, серед яких є і рукояті ножів.

Через тривале перебування в грунті матеріал набув дуже нестабільної структури – емаль отримала кам'яну твердість, а дентин, навпаки, став пухким. Але сучасні технології стабілізації матеріалів допомогли перетворити зуби мамонта на чудову основу для створення розкішних рукояток ножів. Полімерний композит забезпечує виробам стійкість до корозії та вологи, а природна основа дає унікальну текстуру та вигадливий візерунок.

3%C2%A0%E2%80%94%20%D1%81%D0%B5%D1%80%D0%B5%D0%B4%D0%BD%D1%94.jpg)

Особливості матеріалу

Для створення різноманітних виробів використовують корінні зуби мамонта. Зовні вони схожі на зуби слона, проте набагато більше мають інший відтінок. З урахуванням історичної цінності та рідкості бивень мамонта цінується особливо високо, оскільки ця тварина вимерла задовго до нашої ери. Бивні доісторичних гігантів можна зустріти не тільки в палеонтологічних музеях, а й на прилавках ювелірних магазинів, їх застосовують для прикраси інтер'єру, використовують для створення різноманітних декоративних елементів - зрозуміло, не в первозданному вигляді, а в обробленому.

Вік матеріалу, за даними вчених, становить 10-40 тисяч років. Як жили мамонти, сьогодні вивчено не до кінця. Проте знайдені вченими останки цих гігантів, їхні кістки, зуби, навіть цілі туші дозволили вченим серйозно просунутися у цій галузі досліджень. Наявні дані дозволили дізнатися, який був у ссавців зовнішній вигляд, чим вони харчувалися, в яких кліматичних умовах жили, які мали особливості поведінки (наприклад, вели вони стадне або одиночне існування).

Мамонт харчувався практично тим самим, чим і сучасний слон: його раціон складала рослинна їжа. У світі тварина могла б харчуватися хвойними рослинами. Вони воліли грубий корм, який легко пережовували своїми сильними щелепами і зубами, схожими на великі пластини. Цікавою особливістю організму мамонта було те, що в міру зношування старого зуба виростав новий, який зміщував колишній і займав його місце. Таким чином, тварина могла змінити зуби кілька разів за життя. Цілком усі зуби змінювалися приблизно в десятирічний проміжок, а середня тривалість життя мамонта була 40 років. Інакше кажучи, одна тварина могла пережити в середньому чотири повні зміни корінних зубів. Саме завдяки цій особливості люди часто знаходять окремі зношені мамонтові зуби, але не зустрічають інших його слідів.

Зовнішній вигляд

Якщо розглянути зуб мамонта, то можна побачити неоднорідну поверхню з ребристими краями. Кістка, емаль та м'яка тканина в даному випадку чергуються. Матеріал має досить складну структуру:

Основою його є дентин.

Шар дентину покритий захисною емаллю.

Варто відзначити, що у мамонта було всього 4 корінні зуби та 2 бивні, які виступали назовні і служили в основному для самооборони.

Після спеціальної обробки корінний зуб можна використовуватиме виготовлення різноманітних прикрас виробів. Щільність матеріалу дуже висока і нагадує камінь. Для того, щоб обробити такий виріб, майстру потрібно витратити чимало сил і часу.

Стабілізація сировини

Щоб зуб та бивень у процесі використання та виготовлення з нього виробу не зруйнувався, застосовують технологію стабілізації. Це відповідальний етап обробки, у якому застосовуються такі технології:

Поліконденсація.

Вакуумна обробка.

Нанесення спеціальних барвників.

Всі порожнечі зуба наповнюються полімерною речовиною, за рахунок якої основа набуває надійного захисту від кліматичних впливів. Такий виріб не деформується, на ньому не з'являються тріщини, він стає здатним витримувати високу температуру. Зовнішній вигляд матеріалу також змінюється, стає більш привабливим та неповторним.

До появи цієї технології зуби і кістки мамонта для виготовлення сувенірів використовувалися рідко, тому що не мали достатньої міцності через велику кількість тріщин і розшарування всередині. Крім цього, високу твердість має зубна емаль, яка при обробці швидко призводить до непридатності пили. Стабілізований виріб набагато простіше піддавати подальшій обробці. Зуб мамонта став особливо популярним при виготовленні рукояток ножів. Він виглядає незвичайно, привабливо, а якщо додати барвник, можна створити унікальний візерунок, здатний надати навіть такій рідкісній речі особливої індивідуальності.

G10 — в ножах ручної роботи: якість, стиль, сучасність

Що це за матеріал?

G10 — легкий і твердий матеріал, який характеризується поверхнею текстурованою і особливою практичністю. Його використовують для створення рукояток на різних видах ножів – складні та цілісні, з додатковими елементами.

В основі — армований під тиском склотканиною компаунд. Волокнистість структури надає матеріалу жорсткості. Для підвищення важливих експлуатаційних характеристик при виготовленні рукояток до складу додатково додаються спеціальні хімічні сполуки, що зміцнюють. Матеріал не горючий, має більш високі характеристики міцності — на вигин, розрив і удар.

G10 формується за шарами. Це дозволяє фарбувати накладку в один або кілька кольорів, створюючи цікаві візуальні ефекти багатошаровості виробу. Зовні він нагадує мікарту — ще один популярний матеріал, з якого виготовляють накладки ножів ручної роботи «РоС»

Особливості виробництва накладок з G10

Більшість виробників піддають готові накладки з G10 піскоструминної обробки, що оголює структуру скловолокна. У результаті рукоятка набуває шорсткої поверхні, завдяки чому виключається ковзання в руці і забезпечується комфортне і безпечне використання ножів. Після фінішної обробки поверхня накладки може потьмяніти. Для відновлення яскравого, ефектного зовнішнього вигляду на останній стадії виготовлення вона покривається олією або полірується.

Майстер використовує накладки для рукояток із G10 з різними ножовими сталями – ATS 34, CPM154CM, D2, 440C, CPM S30V, 40Х13.

Переваги матеріалу

Цей сучасний матеріал має такі переваги:

- легко витримує навантаження на гнучкість та розтягування;

- має стійкість до ударних навантажень;

- не вбирає вологу;

- відрізняється високою густиною;

- стійкий до радіації та впливу хімікатів;

- має низьку електропровідність;

- не розсихається та не деформується;

- стійка перед високими температурами.

Ще одна перевага даного матеріалу — відмінне співвідношення механічної міцності та малої ваги. Це дозволяє отримувати міцні накладки з хорошими експлуатаційними характеристиками, які не обтяжують ножі.

Якісні та оригінальні накладки з G10 стали чудовою прикрасою ексклюзивних та неповторних ножів майстерні

Якісні та оригінальні сталеві вкладиші є чудовою прикрасою ексклюзивних та неповторних ножів Студія ексклюзивних ножів ручної роботи GARAGE ART в Україні (Україна), яка пропонує замовити та купити в інтернет-магазині https://knife.net.ua або за телефоном. . +380961711010

Рекомендовані товари

Доставка і оплата

Доставка і оплата

Доставка Новою Поштою

Швидкість доставки в будь-яке відділення Нової пошти в Україні фіксується оператором, але зазвичай не перевищує 1-3 календарних днів.

Готівкою

Оплата готівкою при отриманні товару.

Післяплатою на Новій Пошті (при собі необхідно мати паспорт або водійське посвідчення).

Visa и MasterCard

Оплата замовлення на карту Приват Банку.

Доставка товару можлива тільки після підтвердження платежу.

, купити замовити в Україні_заст-1280x720.png)

, купити замовити в Україні28 — середнє-1280x720.jpg)

, купити замовити в Україні27 — середнє-1280x720.jpg)

, купити замовити в Україні26 — середнє-1280x720.jpg)

, купити замовити в Україні2 — середнє-1280x720.jpg)

, купити замовити в Україні22 — середнє-1280x720.jpg)

, купити замовити в Україні4 — середнє-1280x720.jpg)

, купити замовити в Україні20 — середнє-1280x720.jpg)

, купити замовити в Україні29 — середнє-1280x720.jpg)

, купити замовити в Україні21 — середнє-1280x720.jpg)

, купити замовити в Україні24 — середнє-1280x720.jpg)

, купити замовити в Україні18 — середнє-1280x720.jpg)

, купити замовити в Україні12 — середнє-1280x720.jpg)

, купити замовити в Україні23 — середнє-1280x720.jpg)

, купити замовити в Україні10 — середнє-1280x720.jpg)

, купити замовити в Україні13 — середнє-1280x720.jpg)

, купити замовити в Україні19 — середнє-1280x720.jpg)

, купити замовити в Україні1 — середнє-1280x720.jpg)

, купити замовити в Україні25 — середнє-1280x720.jpg)

, купити замовити в Україні14 — середнє-1280x720.jpg)

, купити замовити в Україні15 — середнє-1280x720.jpg)

, купити замовити в Україні16 — середнє-1280x720.jpg)

, купити замовити в Україні17 — середнє-1280x720.jpg)

, купити замовити в Україні34 — середнє-1280x720.jpg)

, купити замовити в Україні33 — середнє-1280x720.jpg)

, купити замовити в Україні32 — середнє-1280x720.jpg)

, купити замовити в Україні30 — середнє-1280x720.jpg)

, купити замовити в Україні31 — середнє-1280x720.jpg)

, купити замовити в Україні11 — середнє-1280x720.jpg)

, купити замовити в Україні_заст-100x100.png)

, купити замовити в Україні28 — середнє-100x100.jpg)

, купити замовити в Україні27 — середнє-100x100.jpg)

, купити замовити в Україні26 — середнє-100x100.jpg)

, купити замовити в Україні2 — середнє-100x100.jpg)

, купити замовити в Україні22 — середнє-100x100.jpg)

, купити замовити в Україні4 — середнє-100x100.jpg)

, купити замовити в Україні20 — середнє-100x100.jpg)

, купити замовити в Україні29 — середнє-100x100.jpg)

, купити замовити в Україні21 — середнє-100x100.jpg)

, купити замовити в Україні24 — середнє-100x100.jpg)

, купити замовити в Україні18 — середнє-100x100.jpg)

, купити замовити в Україні12 — середнє-100x100.jpg)

, купити замовити в Україні23 — середнє-100x100.jpg)

, купити замовити в Україні10 — середнє-100x100.jpg)

, купити замовити в Україні13 — середнє-100x100.jpg)

, купити замовити в Україні19 — середнє-100x100.jpg)

, купити замовити в Україні1 — середнє-100x100.jpg)

, купити замовити в Україні25 — середнє-100x100.jpg)

, купити замовити в Україні14 — середнє-100x100.jpg)

, купити замовити в Україні15 — середнє-100x100.jpg)

, купити замовити в Україні16 — середнє-100x100.jpg)

, купити замовити в Україні17 — середнє-100x100.jpg)

, купити замовити в Україні34 — середнє-100x100.jpg)

, купити замовити в Україні33 — середнє-100x100.jpg)

, купити замовити в Україні32 — середнє-100x100.jpg)

, купити замовити в Україні30 — середнє-100x100.jpg)

, купити замовити в Україні31 — середнє-100x100.jpg)

, купити замовити в Україні11 — середнє-100x100.jpg)

%2C%20%D0%BA%D1%83%D0%BF%D0%B8%D1%82%D0%B8%20%D0%B7%D0%B0%D0%BC%D0%BE%D0%B2%D0%B8%D1%82%D0%B8%20%D0%B2%20%D0%A3%D0%BA%D1%80%D0%B0%D1%96%CC%88%D0%BD%D1%9623%C2%A0%E2%80%94%20%D1%81%D0%B5%D1%80%D0%B5%D0%B4%D0%BD%D1%94.jpg)

-300x300.png)

мисливський ніж/ПЕРО_2 мисливський ніж111-300x300.jpg)

/КЛОНДАЙК (шукач скарбів) н6іж ручної роботи майстра студії ножів Павла Гончаренка-300x300.png)

-300x300.png)

— середнє 2-300x300.jpg)

-600x600.png)

_заст-600x600.png)

9-300x300.jpg)

6-300x300.jpg)