ВОГОНЬ ніж ручної роботи майстра студії GARAGE ART, Сталь ® N690™ 60-61 HRC

- Виробник: Студія ексклюзивних ножів ручної роботи GARAGE ART

- Модель: ВОГОНЬ - ніж ручної роботи GARAGE ART

| Загальна довжина клинка mm: | 250±05 мм |

| Матеріал леза | Сталь Bohler N690 мартенситна, легована кобальтом сталь, виробництва компанії Bohler-Uddeholm AG |

| Твердість клинка (метал): | Загартованість - 60-61 HRC |

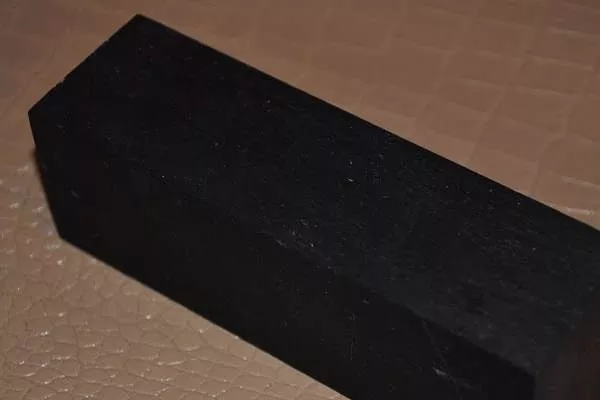

| Матеріал руків'я: | Накладки G-10, чорного-синьго кольору, закріплені на нержавіючі стяжки. Темляк паракорд. (За бажанням можна додати бусини). |

| Довжина леза | 130±05 мм |

- Наявність: В наявності

Доступні варіанти

Опис

ТЕХНІЧНІ ХАРАКТЕРИСТИКИ:

Brand: Студія ексклюзивних ножів ручної роботи GARAGE ART

Кут заточення леза: Загострений на 36' градусів

Спуски: Прямі, подовжній долотер (дол, фуллер) - зменшення ваги ріжучого виробу, наприклад, донна шабля зменшує його вагу майже на 30%; зменшення поверхні тертя; естетика чи навіть традиція – всі погодяться, що це вилучення надає ножу іншого вигляду;можливість виправлення балансування ножа)

Зведення: 0.4-0.5 мм

Твердість леза: 60-61 HRC

Загальна довжина: 250 мм

Довжина леза: 130 мм

Ширина леза: 36 мм

Товщина леза: 4.5 мм

Довжина руків'я: 120 мм

Товщина руків'я: 21 мм

Матеріал больстера (гарда) та тильника: Виготовлені з G 10

Матеріал руків'я: Накладки G-10, чорного-синьго кольору, закріплені на нержавіючі стяжки. Темляк паракорд. (За бажанням можна додати бусини).

Просочення руків'я: Відсутнє

Покриття руків'я: Шліфування

Отвір для шнурка (під темляк): Є

Піхви: Натуральна шкіра рослинного дублення 4.0 мм, оброблена аппретурою для захисту від води та просочена захисними розчинами, жировоскове просочення, прошита вощеною ниткою. Ручне тиснення та художнє оформлення фактури - ручна робота. Фініш Апретурою. Вільний підвіс

Модель: ВОГОНЬ ніж ручної роботи майстра студії GARAGE ART (Назар Бойко), купити замовити в Україні (Сталь ® N690™ 60-61 HRC)

Номер моделі: 011

Країна народження: Україна

Майстер: Майстер Назар Бойко, студія ножів "GARAGE ART", м. Львів, Україна. Студія ексклюзивних ножів ручної роботи GARAGE ART

Найкраще використання: Багатофункціональний: полювання, рибальство, туризм, домашнє господарство - нарізка, тощо.

Стан ножа: Новий

Ціна вказана з піхвами.

Заточений ніж – не є холодною зброєю.

Наші ножі дуже гострі, тому відкривайте та використовуйте дуже обережно. Ми не несемо відповідальності за травми, пов'язані з використанням наших ножів.

Наша продукція призначена для легального використання лише відповідальними покупцями. Ми не продаватимемо наші продукти особам молодше 18 років.

Наявність регулярно змінюється, при підтвердженні Вашого замовлення ми повідомимо про наявність або термін готовності товару. Виріб може трохи відрізнятися від представленого на фото.

Особливості сталі N690

Мартенситна легована сталь N690 виробляється корпорацією Воhlег-Uddeholm Gmbh & Со, що має свої підприємства в Австрії, Німеччині, Південній та Північній Америці. Друга назва сплаву це австрійська кобальтова нержавіюча сталь. Завдяки високій якості та експлуатаційним характеристикам та плюсам її успішно реалізують у багатьох країнах світу для виготовлення ножів та інших цілей.

Сталь виготовляється за технологією електрошлакової переплавки. Має рівномірно розподілену карбідну структуру кристалічної решітки за відсутності шкідливих домішок. В результаті термічної обробки та кування ударна в'язкість матеріалу збільшується без втрати твердості. Наявність легуючих добавок у хімічному складі сталі забезпечує стійкість до корозії.

Галузь застосування

Сталь визнана хорошим матеріалом для серійного виготовлення довгомірних та тактичних ножів, технічні характеристики яких допускають експлуатацію у важких та екстремальних умовах. Леза зі сталі N690 здатні витримувати не тільки поздовжні, а й сильні бічні навантаження при дії на злам і проворотах.

Завдяки стійкості до впливу корозії та агресивних середовищ сталь застосовується при виготовленні ножів для дайвінгу, гарпунів для підводного полювання та іншого спортивного обладнання.

Цю сталь застосовують при виготовленні ножів такі відомі європейські бренди, як Вокег, Spyderco, Вепсhmade та Ехtгеmа Ratio. Виготовлені леза мають прекрасні ріжучі властивості, міцні, довговічні, добре заточуються і тримають край. Наявність легуючих елементів у складі забезпечило високу корозійну стійкість за збереження пластичності. При необхідності існує можливість термічного загартування до 60 НКР.

Техніко-фізичні характеристики сплаву дозволяють використовувати його в машинобудуванні для виготовлення інструменту, фрез, свердел, деталей підшипників та відповідальних вузлів, що працюють при високих механічних навантаженнях. Сталь відрізняється підвищеною зносостійкістю та допускає можливість термічної обробки.

Стійкість до впливу вологи та хімічних речовин дозволяє застосовувати сталь у харчовій та фармацевтичній промисловості для виготовлення ріжучого інструменту та подрібнювачів. При цьому враховується екологічна чистота матеріалу та повна відсутність домішок.

АНАЛОГИ

За своїм складом steel N690 є близьким аналогом російської сталі 95X18, німецької Х102СгМо17, японських / (3-10 і А115-10, французької 2100СО17, американської 440 С. У Швеції виробляють аналог Sandvic 12С27).

СКЛАД

Сталь N690 містить:

■ 1,08% вуглецю (С), який надає твердості матеріалу та підвищує міцність;

■ 17,3% хрому (Сг) для отримання антикорозійних властивостей, підвищення зносостійкості та зміни умов загартовування;

■ 1,1% молібдену (Мо) для зниження крихкості, підвищення пластичності та стійкості до впливу високих температур;

■ 0,1% ванадію (V) для посилення пружності металу та інертності до дії агресивних середовищ;

■ 1,5% кобальту (Со) підвищення жароміцності і поліпшення механічних властивостей;

■ 0,4% марганцю (Мп) підвищення твердості;

■ 0,4% кремнію (5|) для покращення стабільності сплаву та посилення зносостійкості.

Наявність кобальту в хімічному складі металу робить кристалічну структуру N690 більш однорідною та стійкою до механічних навантажень.

ПЛЮСИ ТА МІНУСИ СТАЛІ N690 ДЛЯ НОЖІВ

Використання австрійської сталі N690 дозволяє виготовляти якісні нержавіючі ножі різного призначення. Завдяки своїм фізико-технічним властивостям матеріал добре обробляється, здатний до термічної обробки, не схильний до корозії і продається за доступною ціною.

5*ее1 N690 це один із кращих сплавів для виготовлення красивих зносостійких клинків. Просте заточування та тривале збереження гостроти кромки роблять користування простим та зручним. Ви ніколи не пошкодуєте про купівлю або виготовлення ножа із цієї сталі.

Види поставок

Висока якість сталі Вohler N690 забезпечена застосуванням унікальної технології прокатки, розробленої виробником. Металеві листи піддаються багаторазовій гарячій обробці з прокаткою в поздовжньому та поперечному напрямку. Після цього проводиться холодне нарізування матеріалу на смуги.

Спеціально для виготовлення ножів сталь марки N690 поставляється на ринок металопрокату у вигляді сталевих смуг товщиною 3-5 мм, шириною 20-50 мм та довжиною від 250 до 1000 мм. Поперечний переріз смуг прямокутний або з підготовленим поздовжнім скосом, який позбавити виконання ковальських робіт при виготовленні леза. Сталь може мати попередню термообробку або без неї.

Все це дуже зручно, оскільки не вимагає виконання операцій з різання великих листів, дозволяє точно визначати кількість необхідного матеріалу і знижує кількість відходів.

Смуги продаються поштучно. Вартість залежить від геометричних розмірів виробу, товщини та видів попередньої заводської обробки. Для продукції металообробної промисловості здійснюються постачання листа товщиною 2-8 мм заявленого у договорі розміру. За потреби можна замовити будь-який аналог сталей типу N690. Металевий лист продається на вагу.

Породи дерева для рукояті ножа

Для виготовлення рукоятей ножів використовується велика кількість різних сортів дерева, таких як карельська береза, бубінга, венге, стабілізований граб, падук, лосиний ріг, сапеле, палісандр, береста та інші. Будь-який навіть найкращий ніж, якої б міцності він не мав. Виявиться малопридатним для практичного застосування, якщо у нього погана рукоятка. Формула гарного ножа = клинок з надійної та міцної сталі + рукоятка, що зручно лежить у руці та з правильно підібраного матеріалу. Для риболовлі гарний ніж з рукояттю з берести, а для полювання краще дерев'яна рукоять, на зимовому полюванні ніж з рогу холодитиме руку без рукавички. Розглянемо докладніше найпопулярніші породи деревини.

Стабілізований граб імітує текстуру ебенового дерева. Ебен є однією з найбільш цінних порід деревини, що виростають в Африці. Висока ціна обумовлена, як рідкістю породи, тим, що деревина має велику кількість заболоні (шар дерева між корою і ядром), що дозволяє використовувати тільки порядком 30% стовбура для виробів. Крім того, ебенове дерево схильне до розтріскування, що для рукояті ножа неприйнятне. Чорний граб завдяки просочення смолами повторює текстуру ебену і не схильний до розтріскування, крім того рукояті з граба надзвичайно міцні завдяки високій щільності деревини, що робить його ідеальним матеріалом для виконання рукоятей ножів у чорному кольорі.

На фото (ліворуч-праворуч): залізне дерево, брусок з грабу стабілізованого смолами, рукояті зі стабілізованого граба.

Венге - це тропічний сорт деревини, що часто застосовується для виготовлення рукоятей ножів, не тільки через красиву структуру, але ще через свої фізичні властивості. Характеризується надзвичайно грубою текстурою із прямими прожилками. Має надзвичайно високу опірність на ударні навантаження, що дозволить рукояті прослужити так само довго, як і клинку ножа. Стійка до гниття. Колірна гама може сильно відрізнятися від золотисто-коричневого до темно-коричневого з чорними прожилками, для виготовлення рукоятей ножів використовуються заготовки з серцевини стовбура.

Бубінга чи інакше африканське рожеве дерево має гарну і надзвичайно насичену структуру з гарними прожилками рожевого та червоного кольору. Для рукояток підходить, як серцевина, заболонь дерева, в даному випадку, єдиною відмінністю буде колір, заболонь на кілька відтінків світліше. Надзвичайно щільний (від 800 до 960 кг/м3) і важкий сорт дерева, але рукояті з бубінгу виглядають ґрунтовно і солідно. Не схильний до розтріскування, добре пручається волозі та грибку.

Падук - надзвичайно поширене в південній півкулі дерево. Одна з найбільш водостійких порід деревини (при контакті з ґрунтом, здатна прослужити в середньому 25 років), добре підходить до ножів для риболовлі полювання в дощову та вологу погоду, тому що не ковзає в руці, навіть при попаданні вологи.

На фото (ліворуч-праворуч) рукояті з: бубінгу, венге, падука.

Одним із найдавніших матеріалів для виготовлення рукоятей ножів є кістка та роги тварин. Як і деревина матеріал природний, найчастіше для рукоятей ножів використовується лосиний ріг. Дуже складний в порівнянні з деревом матеріал для обробки, зате овчинка коштує вичинки, рукояті виходять ексклюзивними і не схожими один на одного, якщо зі стовбура дерева можна зробити величезну кількість рукоятей, то з рогу одного лося дуже обмежена кількість.

При замовленні ножа з рукояттю з лосиного рогу варто розуміти, що вона може дещо відрізнятися від тієї, що ви побачите на фотографії, тут як із відбитками пальців у людини двох абсолютно однакових не буває.

Єдиним мінусом даного матеріалу можна, мабуть, порахувати лише незручність використання на полюванні взимку, на морозі рукоятка з рогу дуже сильно охолоджується і гола рука тримати його буде дуже не комфортно.

Береста практична і зручна як матеріал для рукояті, головною її перевагою буде те, що рукоятка не ковзає в руці, навіть якщо на неї потрапила велика кількість води. Ну і безумовно, береза-це наше рідне, а не деревина з Африки та тропіків. Береста характерно містить велику кількість дьогтю, що наділяє її дезінфікуючими властивостями та захищає її від гниття, ніякі паразити та грибки на бересті не приживуться. Надзвичайно хороший матеріал, для рибальських ножів, невеликий ніж із берестяною рукояттю, може залишитися на плаву, потрапивши у воду.

Сапале - ще один з сортів деревини родом з Африки. Надзвичайно красива структура палітра від світло-рожевого до червонувато-коричневого кольору. Не схильна до розтріскування має високу твердість, від 4,1 до 4,5 одиниць за Брінеллем. Всі представлені на сайті сорти деревини, чудово підходять для виготовлення рукоятей ножа і переважно вибір ножа з конкретною рукояттю, має естетичне значення, залежно від ваших особистих уподобань.

На фото (ліворуч-праворуч) рукояті з: лосиного рогу, берести, саппеле.

Рукоятки також можуть бути виконані з декількох сортів деревини, зі вставками "сенвдич" поруч з гардою ножа, або в середині рукояті. Всі представлені на сайті сорти деревини, чудово підходять для виготовлення рукоятей ножа і переважно вибір ножа з конкретною рукояттю, має естетичне значення, залежно від ваших особистих уподобань.

G10 — в ножах ручної роботи: якість, стиль, сучасність

Що це за матеріал?

G10 — легкий і твердий матеріал, який характеризується поверхнею текстурованою і особливою практичністю. Його використовують для створення рукояток на різних видах ножів – складні та цілісні, з додатковими елементами.

В основі — армований під тиском склотканиною компаунд. Волокнистість структури надає матеріалу жорсткості. Для підвищення важливих експлуатаційних характеристик при виготовленні рукояток до складу додатково додаються спеціальні хімічні сполуки, що зміцнюють. Матеріал не горючий, має більш високі характеристики міцності — на вигин, розрив і удар.

G10 формується за шарами. Це дозволяє фарбувати накладку в один або кілька кольорів, створюючи цікаві візуальні ефекти багатошаровості виробу. Зовні він нагадує мікарту — ще один популярний матеріал, з якого виготовляють накладки ножів ручної роботи «РоС»

Особливості виробництва накладок з G10

Більшість виробників піддають готові накладки з G10 піскоструминної обробки, що оголює структуру скловолокна. У результаті рукоятка набуває шорсткої поверхні, завдяки чому виключається ковзання в руці і забезпечується комфортне і безпечне використання ножів. Після фінішної обробки поверхня накладки може потьмяніти. Для відновлення яскравого, ефектного зовнішнього вигляду на останній стадії виготовлення вона покривається олією або полірується.

Майстер використовує накладки для рукояток із G10 з різними ножовими сталями – ATS 34, CPM154CM, D2, 440C, CPM S30V, 40Х13.

Переваги матеріалу

Цей сучасний матеріал має такі переваги:

- легко витримує навантаження на гнучкість та розтягування;

- має стійкість до ударних навантажень;

- не вбирає вологу;

- відрізняється високою густиною;

- стійкий до радіації та впливу хімікатів;

- має низьку електропровідність;

- не розсихається та не деформується;

- стійка перед високими температурами.

Ще одна перевага даного матеріалу — відмінне співвідношення механічної міцності та малої ваги. Це дозволяє отримувати міцні накладки з хорошими експлуатаційними характеристиками, які не обтяжують ножі.

Якісні та оригінальні накладки з G10 стали чудовою прикрасою ексклюзивних та неповторних ножів майстерні

Якісні та оригінальні сталеві вкладиші є чудовою прикрасою ексклюзивних та неповторних ножів Студія ексклюзивних ножів ручної роботи GARAGE ART в Україні (Україна), яка пропонує замовити та купити в інтернет-магазині https://knife.net.ua або за телефоном. . +380961711010

Рекомендовані товари

Доставка і оплата

Доставка і оплата

Доставка Новою Поштою

Швидкість доставки в будь-яке відділення Нової пошти в Україні фіксується оператором, але зазвичай не перевищує 1-3 календарних днів.

Готівкою

Оплата готівкою при отриманні товару.

Післяплатою на Новій Пошті (при собі необхідно мати паспорт або водійське посвідчення).

Visa и MasterCard

Оплата замовлення на карту Приват Банку.

Доставка товару можлива тільки після підтвердження платежу.

, купити замовити в Україні — середнє-1280x720.jpg)

, купити замовити в Україні3 — середнє-1280x720.jpg)

, купити замовити в Україні2 — середнє-1280x720.jpg)

, купити замовити в Україні9 — середнє-1280x720.jpg)

, купити замовити в Україні7 — середнє-1280x720.jpg)

, купити замовити в Україні6 — середнє-1280x720.jpg)

, купити замовити в Україні4 — середнє-1280x720.jpg)

, купити замовити в Україні5 — середнє-1280x720.jpg)

, купити замовити в Україні26 — середнє-1280x720.jpg)

, купити замовити в Україні24 — середнє-1280x720.jpg)

, купити замовити в Україні8 — середнє-1280x720.jpg)

, купити замовити в Україні25 — середнє-1280x720.jpg)

, купити замовити в Україні23 — середнє-1280x720.jpg)

, купити замовити в Україні22 — середнє-1280x720.jpg)

, купити замовити в Україні21 — середнє-1280x720.jpg)

, купити замовити в Україні20 — середнє-1280x720.jpg)

, купити замовити в Україні19 — середнє-1280x720.jpg)

, купити замовити в Україні18 — середнє-1280x720.jpg)

, купити замовити в Україні17 — середнє-1280x720.jpg)

, купити замовити в Україні16 — середнє-1280x720.jpg)

, купити замовити в Україні15 — середнє-1280x720.jpg)

, купити замовити в Україні14 — середнє-1280x720.jpg)

, купити замовити в Україні11 — середнє-1280x720.jpg)

, купити замовити в Україні13 — середнє-1280x720.jpg)

, купити замовити в Україні10 — середнє-1280x720.jpg)

, купити замовити в Україні — середнє-100x100.jpg)

, купити замовити в Україні3 — середнє-100x100.jpg)

, купити замовити в Україні2 — середнє-100x100.jpg)

, купити замовити в Україні9 — середнє-100x100.jpg)

, купити замовити в Україні7 — середнє-100x100.jpg)

, купити замовити в Україні6 — середнє-100x100.jpg)

, купити замовити в Україні4 — середнє-100x100.jpg)

, купити замовити в Україні5 — середнє-100x100.jpg)

, купити замовити в Україні26 — середнє-100x100.jpg)

, купити замовити в Україні24 — середнє-100x100.jpg)

, купити замовити в Україні8 — середнє-100x100.jpg)

, купити замовити в Україні25 — середнє-100x100.jpg)

, купити замовити в Україні23 — середнє-100x100.jpg)

, купити замовити в Україні22 — середнє-100x100.jpg)

, купити замовити в Україні21 — середнє-100x100.jpg)

, купити замовити в Україні20 — середнє-100x100.jpg)

, купити замовити в Україні19 — середнє-100x100.jpg)

, купити замовити в Україні18 — середнє-100x100.jpg)

, купити замовити в Україні17 — середнє-100x100.jpg)

, купити замовити в Україні16 — середнє-100x100.jpg)

, купити замовити в Україні15 — середнє-100x100.jpg)

, купити замовити в Україні14 — середнє-100x100.jpg)

, купити замовити в Україні11 — середнє-100x100.jpg)

, купити замовити в Україні13 — середнє-100x100.jpg)

, купити замовити в Україні10 — середнє-100x100.jpg)

%2C%20%D0%BA%D1%83%D0%BF%D0%B8%D1%82%D0%B8%20%D0%B7%D0%B0%D0%BC%D0%BE%D0%B2%D0%B8%D1%82%D0%B8%20%D0%B2%20%D0%A3%D0%BA%D1%80%D0%B0%D1%96%CC%88%D0%BD%D1%9624%C2%A0%E2%80%94%20%D1%81%D0%B5%D1%80%D0%B5%D0%B4%D0%BD%D1%94.jpg)

-300x300.png)

мисливський ніж/ПЕРО_2 мисливський ніж111-300x300.jpg)

/КЛОНДАЙК (шукач скарбів) н6іж ручної роботи майстра студії ножів Павла Гончаренка-300x300.png)

-300x300.png)

— середнє 2-300x300.jpg)

-600x600.png)

_заст-600x600.png)

9-300x300.jpg)

6-300x300.jpg)